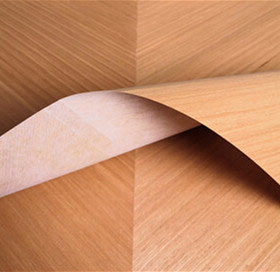

Backed Veneer

The backed veneer is a real wood veneer bond with fleece (non-woven fabric/textiles) or kraft paper. The backing is applied to keep the paper thin wood veneer flexible and not easy to split.

Besides, the backed veneer has a competitive price compared with a 0.5 mm thick common natural veneer. So it will save total costs for your entire woodworking projects.

There are 2 types of backing, they can be the back support layers of wood veneer. Kraft paper, and fleece (non-woven fabric/textiles).

For the face veneer material, we use natural wood veneer and reconstituted veneer. The common thickness is 0.15mm to 0.25mm.

People like to buy 0.2 mm to 0.25mm thickness fleece back veneer sheets and paperback veneer. For interior decoration or woodworking DIY. While massive used in building and construction. For doors, wood cabinets, furniture, wallcovering panels, veneering plywood, veneered MDF, etc.

Download PDF : 15 types of fleece/paper backed wood veneer

Download PDF : 10 points checklist before you buy wood veneers

2 Main Types of Backed Veneer

Fleece Backed Veneer

Fleece back veneer is a real wood veneer sheet bond with nonwoven fabric.

For fleece, people also name it non-woven fabric or textile.

We use 25 gsm and 40 gsm quality white non-woven fabric. Bonding with natural wood veneer or reconstituted veneer.

But the most popular is a 25 gsm non-woven fabric backed veneer.

You can find fleece back engineered veneer, fleece back thin natural wood veneer, fleece back bamboo veneer, fleece back cross cut veneer, fleece back burl veneer, wood veneer layons with fleece back, fleece back edgebanding veneer roll, fleece back wrapping veneer roll, geometric veneer sheet with fleece backing.

You will see fleece-backed veneer is applied to the veneered door and furniture.

Paper Back Veneer

Paper back veneer is real wood veneer bond with kraft paper backing.

You can find 4 types of paper-backed veneers from our wood veneer supplies.

> Paper backing engineered veneer, the face wood veneer is 0.2mm thin or 0.5mm thick engineered veneers.

> Paper back thin natural veneer, the face wood veneer is 0.15mm to 0.2mm thickness raw natural veneer.

> Paperbacked matching thick natural veneer. The faces multiple veneer edges spliced sheet by sheet.

> Burl wood veneer sheet with paper backing support.

For the kraft paper, we use 10 mil thickness kraft paper as a back support layer.

The individual wood veneer sheets can make a full-width sheet. This is the main feature of the paperbacked veneer. You can get 2x8ft (2500x610mm) and 4x8ft (2500x1220mm) standard paper backed veneer sheet.

16 Related Backed Veneer Products

Fleece Back Engineered Veneer

Fleece Back Walnut Veneer

Fleece Back Bamboo Veneer

Cross Cut End Grain Veneer

Fleece Back Burl Veneer

Fleece Back Burl Veneer

Fleece Back Edge Banding

Fleece Back Profile Wrapping

Fleece Back Pre-finished Veneer

Fleece Back Woven Veneer

Fleece Back Geometric Veneer

Paper Back Engineered Veneer

Paper Back Walnut Veneer

Paper Back Spliced Veneer

Paper Back Burl Veneer

White Paper Backed Veneer

Nowadays, a 0.2 mm fleece back wood veneer and paperbacked veneer. They are very common in wood veneer door and wood veneer furniture carpentry.

It is easy to apply fleece/paper backed wood veneers. Because they have good features of flexible and strong.

They also have max four foot wide, so that will be very easy to bond on the substrate.

But the bubbling problems always happen. When applying the wood veneer bonded to substrates not smooth.

If you want to use thin fleece/paper backed veneers, You should buy good quality plywood or MDF with a smooth surface.

In the production of the wood door, cabinet, furniture, and wallcovering. The stability and smooth of the substrate are very important in avoiding veneering problems.

Why Choose Our Backed Wood Veneers

Download PDF : Company Presentation

Download PDF : 15 types of awesome wood veneers

Back to top: Backed Veneer Sheet