Bamboo Veneer

Bamboo veneer is a thin sliced sheet from laminated bamboo blocks.

The bamboo blocks raw materials are made from a common fast growing type of bamboo.

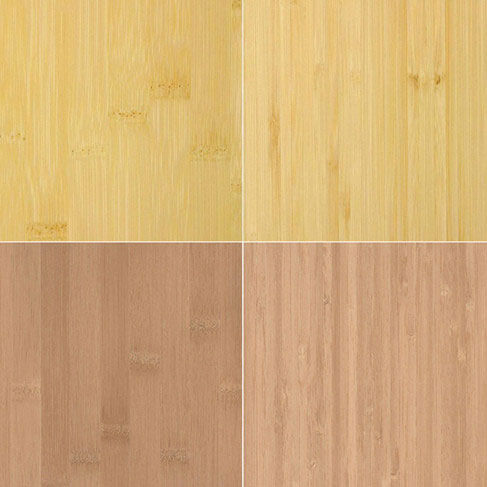

The colors range from pale yellow natural color to darker brown carbonized color.

Ordinarily, the grains you can choose narrow strand vertical or planked horizontal.

All the bamboo thin veneer sheets backed with fleece (non-woven fabric) to avoid cracks.

The standard length is 2500mm, width 430mm. But you can buy spliced wider veneer sheets in 860mm, 1280mm, or customized size.

The thickness of bamboo veneers we can slice 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, and 1.2mm.

As a kind of 100% natural renewable decoration material. Veneer bamboo sheet is a great option for architectural and interior decoration.

In the decoration of wall panels, doors, furniture, cabinets. You can find the application of different types of bamboo grain veneers.

Download PDF: 7 types of bamboo veneer sheets and roll

Download PDF: 10 points checklist before you buy bamboo wood veneers

7 Main Types of Bamboo Veneer

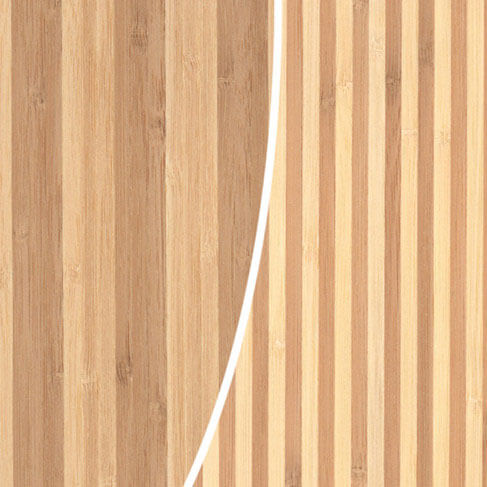

Carbonized Vertical Bamboo Veneer

Carbonized vertical bamboo veneers have narrow vertical grains with darker brown caramel color.

When we talk about vertical bamboo panels or veneers, which are the most common grains.

The narrow bamboo strips’ width is from 6mm to 8mm more or less.

Compare with horizontal planked grains, vertical grains veneer production is not complicated. The most important is vertical veneer has a competitive price.

You can find 3 types of brown caramel colors according to the carbonized processing. There are light carbonized color, medium carbonized color, and deep carbonized dark caramel color.

But the most popular are light carbonized vertical bamboo and medium carbonized vertical bamboo panels and veneers.

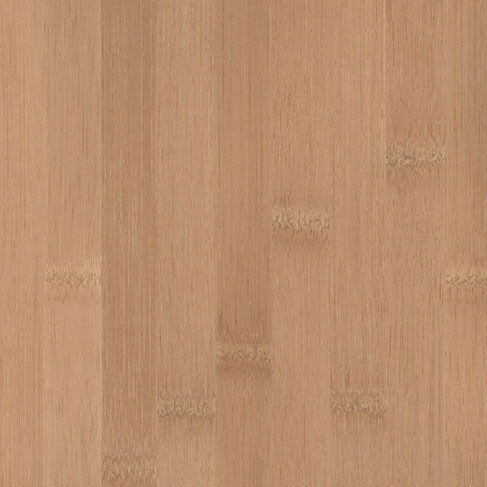

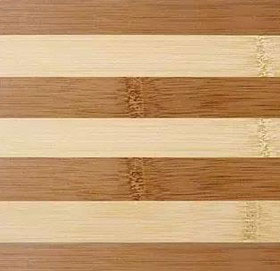

Carbonized Horizontal Bamboo Veneer

Carbonized horizontal bamboo veneers have wide strips of planked patterns.

Horizontal planked bamboo has a much complicated technical request in production. So it is much expensive than the above vertical grain veneer sheets.

Usually, the wide bamboo strips are from 20mm to 25mm.

You can see the visible natural bamboo node on the veneer sheets.

With high temperature and pressure carbonization process. That gives carbonized bamboo a better density and strength.

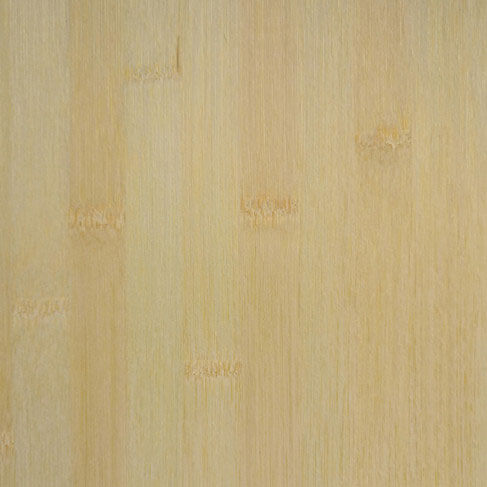

Natural Vertical Bamboo Veneer

Do not want the coffee brown color bamboo veneer sheets? You can consider the natural color bamboo.

The most common and competitive is the natural vertical bamboo.

As earlier mentioned, the bamboo natural veneer has a pale yellow color.

You can find many interior furniture, cabinet, and wall covering with natural vertical bamboo designs.

As we know, Germany, South. Korea, Spain, and Portugal clients like natural color bamboo boards and veneers.

They laminated bamboo thin veneer on MDF or plywood for carpentry work.

Sometimes, they also like to use solid natural bamboo boards.

Natural Horizontal Bamboo Veneer

When you want natural bamboo colors and visible natural bamboo nodes. Natural horizontal bamboo boards and veneers are the great option.

It keeps the natural beauty of bamboo.

You can see more clear natural bamboo nodes on horizontal bamboo panels or veneer sheets.

As early mentioned, horizontal planked bamboo has a much complicated technology of production.

Moreover, natural horizontal bamboo is more complicated than carbonized horizontal bamboo.

Top-quality natural horizontal bamboo veneer sheets are made from top quality bamboo strips. They have less color difference, mineral streaks.

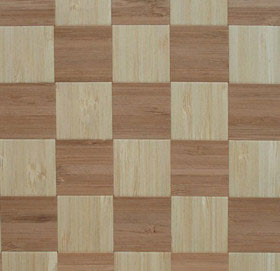

Zebra Grain Bamboo Veneer

Zebra grain bamboo veneer is a combination of natural color bamboo and carbonized brown caramel color bamboo strips.

In fact, the common design is 5-7mm in width two colors bamboo strips glued one by one.

You can name it narrow strips zebra bamboo.

The other design is to glue 3 strips of vertical bamboo planks first, then mix different colors together.

You can name it wide strips zebra bamboo.

If you think solid zebra bamboo board is expensive for your interior decoration projects. I suggest that you can try laminated zebra bamboo thin veneers on plywood or other panels.

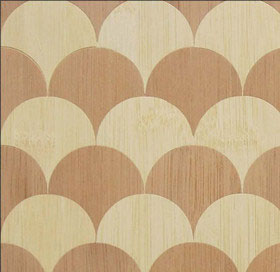

Woven Bamboo Veneer

Woven bamboo veneer is 100% hand made basket-weave veneer sheets.

We can weave different colors and wide strips to design patterns.

You can find woven bamboo sheets are much popular in the USA and Canada in a variety of applications.

For some textured walls, ceilings, furniture, and kitchen surface decoration. You will find bamboo woven veneer sheets give designers a great geometry idea.

As you probably know, all the woven veneer sheets back with fleece. That allows the veneer sheets to be curved and durable.

So if you not only want the natural bamboo or wood for surface decoration. You can consider the woven veneer. Maybe the woven patterns will give you a big idea of imagination.

Bamboo Veneer Roll

Bamboo veneer rolls are the finger-joint bamboo wood veneers in rolls 200 meters standard length or customized length.

The width from 15mm to 60mm veneer roll is for edge banding application.

Besides, the width from 60mm to 300mm bamboo veneers roll is for wrapping profile.

Generally, the thickness can be from 0.25mm to 1.2mm, but the standard thickness is 0.4mm or 0.5mm here in China.

In the manufacture of veneer door, veneer furniture, skirting, and mouldings. Bamboo veneer roll makes all surface and side decoration with the look and feels of solid bamboo. But at less expensive prices than solid bamboo boards.

16 Related Bamboo Veneer Sheets and Roll

Fleece Backed Veneer Bamboo

UV Prefinished Veneer Bamboo

Veneer 1/16

Thick Veneer 1/8

Planked Zebra Bamboo

Woven Bamboo Sheet

Woven Bamboo Wall Covering

Bamboo Matching Veneer

Bamboo Edge Banding Veneer

Bamboo Wrapping Veneer

Bamboo Bend Tube

Bamboo Lamp Shade

Bamboo Boards

Bamboo Wall Covering

Bamboo Office Furniture

Bamboo Hotel Ceiling

Compared with wood materials, China is rich in bamboo.

Nearly one-quarter of the world’s bamboo forest is in China. There are about 48 main types of bamboo species here.

But the most suitable is Moso bamboo, which is characterized by tough, rich flexibility, and fast-growing.

Moso bamboo is the best option for the production of industrial decoration materials.

Baby bamboo grows about 80mm to 100mm every day in the late spring and early summer. After then, they can be used for production materials about 4-6 years later.

Except for traditional bamboo handicrafts, you can find modern furniture and decoration with bamboo boards or bamboo veneered plywood.

Interior bamboo flooring and outdoor bamboo decking are also good options.

Why Choose Our Bamboo Veneer and Roll

Download PDF : Company Presentation

Download PDF : 15 types of awesome wood veneers

Frequently Asked Questions (FAQs)

What is bamboo veneer?

Bamboo veneer is a thinly sliced veneer sheet obtained from precomposed bamboo blocks.

How is bamboo veneer made?

The manufacturing process of bamboo veneer includes the following steps:

- Select Moso bamboo (4-6 years old), then remove branches and leaves.

- Split bamboo into strips and clean them.

- Steam the bamboo strips and dry them to a moisture content of 10-16%.

- Process the bamboo strips with a four-side moulder.

- Glue the bamboo strips and press them into recomposed bamboo blocks.

- Soften the bamboo blocks for slicing.

- Slice veneer sheets from the softened bamboo blocks.

- Apply fleece backing to the veneer sheets.

These steps complete the bamboo veneer manufacturing process.

What is the standard sheet size and thickness available?

The common standard bamboo sheet size is 2500x430mm.

Other available customized sizes:

✔ 2500x640mm

✔ 2500x860mm

✔ 2500x1260mm

The available thickness options range from 0.2mm to 1.2mm, with standard stock sizes of 0.4mm and 0.5mm.

Where can I buy bamboo veneer sheets?

You can find bamboo veneer suppliers in local markets across the USA and Canada. However, for larger quantities and competitive pricing, you may consider importing from suppliers in China.

What is the HS code for bamboo veneers?

The HS code for bamboo veneer in China is 44089013.90.

What is the density of bamboo boards and veneers?

The density of bamboo boards and veneers is approximately 700-750 kg/m³.

How to press bamboo veneer sheets on plywood, MDF, or particle board?

The process of pressing bamboo veneer sheets onto plywood, MDF, or particle board is similar to common wood veneers. However, we recommend conducting a glue test first to determine the optimal pressure, temperature, and pressing time for best results.

Back to top: Bamboo Veneer