Wood veneer is a thin slice of wood, typically less than 3 mm thick, used to cover surfaces and improve the appearance of furniture and other wood products. It provides the look of solid wood while being more cost-effective and versatile.

There are many different wood veneer types and veneer examples, and we cover many of them in our article! At WoodenAve, we specialise in providing premium wood veneers that cater to various design needs.

Key Takeaways

- Common wood species for veneers include oak, maple, cherry, and walnut.

- Wood veneers are used in furniture making, cabinetry, and architectural applications.

- There are many types of wood veneer, including natural and engineered options.

- WoodenAve offers affordable and quality wood veneer products.

What is Wood Veneer?

Wood veneer is a very thin layer of real wood that is cut from a log. It is usually less than 3 mm thick and can be made by slicing or rotary cutting the trunk of a tree. A veneer can be applied to various substrates, such as plywood or particle board, to create a surface that resembles solid wood. This method allows manufacturers to use less valuable wood while still achieving an attractive finish. Veneers are available in many species, offering a variety of colours and grain patterns.

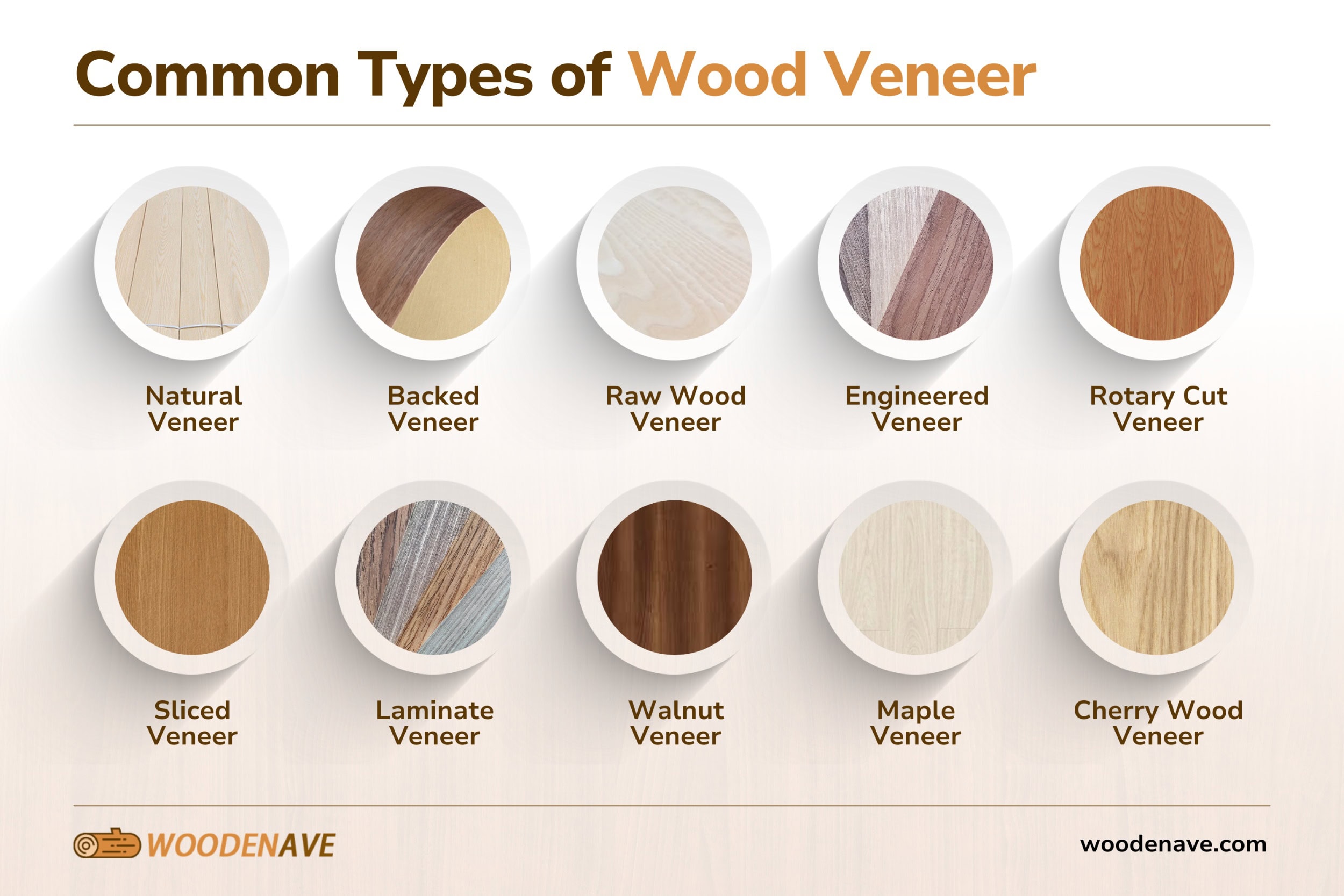

Common Types of Wood Veneer

There are various types of veneer wood, including oak, maple, cherry, and so much more! Here are the most common wood veneer species:

| Type of Veneer | Description |

|---|---|

| Natural Veneer | Real wood showcasing unique grain patterns |

| Backed Veneer | Reinforced with paper or cloth for added strength |

| Raw Wood Veneer | Thin slices without backing |

| Engineered Veneer | Laminated from fast-growing species |

| Rotary Cut Veneer | Continuous sheets produced by peeling |

| Sliced Veneer | Thin sheets cut to highlight grain |

| Laminate Veneer | Multiple layers glued together |

| Walnut Veneer | Rich colour with distinctive grain |

| Maple Veneer | Fine grain with light colour |

| Cherry Wood Veneer | Warm tones that deepen over time |

Natural Veneer

Natural veneer is made from real wood logs and showcases the unique characteristics of each species. This type of veneer retains the natural beauty and grain patterns found in solid wood. It is often used in high-end furniture and cabinetry because it offers an authentic look.

Backed Veneer

Backed veneer has a reinforcing material on one side, such as paper or cloth. This backing adds strength and flexibility, which makes it easier to work with during installation. Backed veneers are less prone to cracking and are ideal for curved surfaces.

Raw Wood Veneer

Raw wood veneer consists of thin slices without any backing. It can be applied to various surfaces and finished like solid wood. This type of veneer is versatile but requires careful handling to prevent damage during application.

Engineered Veneer

Engineered veneer is created from fast-growing tree species that are laminated together to mimic the appearance of more expensive woods. This type of veneer is cost-effective and environmentally friendly, so it’s a popular choice for many applications.

Rotary Cut Veneer

Rotary cut veneer is produced by peeling a log on a lathe, which results in a continuous sheet of veneer. This method maximises yield from the log and produces wide sheets that can be used for large surfaces. The grain pattern tends to be less uniform compared to sliced veneers.

Sliced Veneer

Sliced veneer is made by cutting the log into thin sheets using various slicing techniques. This method highlights the grain pattern and texture of the wood more effectively than rotary cutting, so it’s suitable for decorative applications.

Laminate Veneer

Laminate veneers consist of multiple layers glued together to create a strong surface that can imitate different types of wood. They offer durability and resistance to wear while providing an attractive finish.

Walnut Veneer

Walnut veneer is prized for its striking colour and distinctive grain pattern. It is often used in high-end furniture and cabinetry due to its luxurious appearance and durability.

Maple Veneer

Maple veneer features a fine grain that provides a smooth surface ideal for modern designs. Its light colour can brighten up spaces, making it a popular choice for contemporary furniture.

Cherry Wood Veneer

Cherry wood veneer is known for its warm tones that deepen with age. It has a smooth texture and fine grain, making it suitable for elegant furniture pieces.

Wood Used for Wood Veneer

Various types of wood are used to create veneers, including both hardwoods and softwoods. Common hardwood species include oak, maple, cherry, and walnut, which are valued for their durability and aesthetic appeal. Softwood species like Douglas fir are also used due to their availability and cost-effectiveness.

- Hardwood: Offers strength and beauty; ideal for decorative applications

- Softwood: Generally more affordable; suitable for budget projects

- Exotic Woods: Often used for unique appearances; can be more expensive

The Benefits of Wood Veneer

- Cost Efficiency: Offers the look of expensive wood at a fraction of the price

- Sustainability: Uses less material than solid wood and is more environmentally friendly

- Versatility: Can be applied to several substrates and is suitable for many designs

- Aesthetic Appeal: Showcases beautiful grain patterns and enhances overall decor

- Ease of Use: Lighter than solid wood and easier to handle during installation

The Applications of Wood Veneer

- Furniture Making: Provides an attractive finish for tables, chairs, and cabinets

- Cabinetry: Commonly used in kitchens and bathrooms for stylish cabinets

- Architectural Applications: Used in wall panelling and decorative elements in commercial spaces

- Musical Instruments: Applied in pianos and guitars for aesthetic value

- Interior Design: Improves walls, ceilings, and other surfaces with natural beauty

WoodenAve: Affordable, Quality Wood Veneer

At WoodenAve, we pride ourselves on offering affordable yet high-quality wood veneers suitable for any project. Our range includes various types of veneer sheets made from both common and exotic species, ensuring you find the perfect match for your needs. Get in touch today to discover how our products can enhance your designs!

Common Types of Wood Veneer FAQs

How can I tell what wood veneer I have?

To identify your veneer, examine the wood grain and texture on one side of the veneer, as specific patterns can hint at the types of wood used, such as beech or oak. Look for characteristics like the wood cut or splicing method; decorative veneer often features unique patterns. If the veneer is usually paired with plywood veneer types, it’s a clue to its intended use.

What is the cheapest type of wood veneer?

Softwood veneer, like pine, is often the most affordable option. It is commonly available in wood veneer sheets, making it cost-effective for bulk projects. Veneer also includes simpler finishes that require less intricate match veneer processes.

What are the different grades of veneer wood?

Veneer is graded by quality, with higher grades being natural wood for decorative veneer, while lower grades may come from less refined sheet of wood. Grades also depend on the side of the veneer and its intended use, such as structural versus aesthetic. Factors like splicing, using wood efficiently, and different types of wood veneer determine overall classification.

Back to Top: Common Types of Wood Veneer