Fleece Backed Veneer

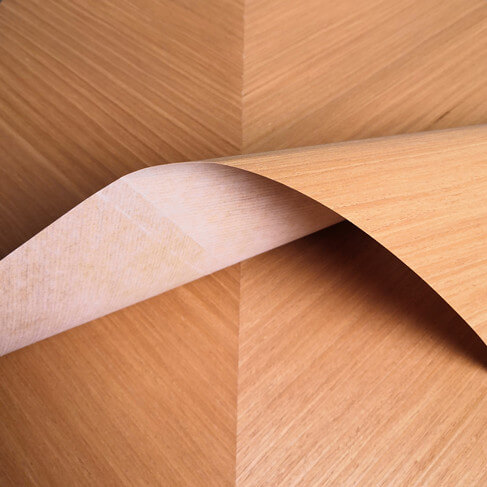

Fleece-backed veneer is a thin wood veneer sheet or roll bonded to a layer of non-woven fabric (fleece). This backing enhances the veneer’s stability, durability, and flexibility, making it ideal for applications like furniture, doors, and profile wrapping.

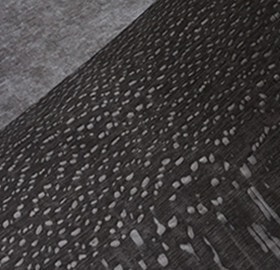

What is Fleece?

Fleece is a type of non-woven textile fabric. When bonded to paper-thin wood veneers, it helps prevent cracking and breaking during handling and application.

Benefits of Fleece Backed Veneer

- Stability: Keeps ultra-thin wood veneers intact and easy to handle.

- Durability: Extends the lifespan of the veneer.

- Flexibility: Allows seamless application on curved or uneven surfaces.

For our products, we use 25 gsm white non-woven fabric as the standard backing for fleece veneers. For added thickness, 40 gsm non-woven fabric is available upon request.

5 Main Types of Fleece Backed Veneer Sheets and Rolls

Fleece Backed Natural Real Veneer

To reduce costs and maximize wood resources, natural wood veneers are cut as thin as possible (as little as 0.1 mm). However, thin veneers can easily crack or break, especially during application.

Fleece backing solves this issue, making even delicate veneers like oak, teak, or rosewood durable and easy to work with. These backed veneers are particularly useful for projects requiring light transparency or for thin wet veneers that are challenging to handle.

Fleece Backed Engineered Veneer

Engineered veneers are known for their consistent color and grain, making them a reliable choice for large-scale projects.

- Custom Sizes: Available in standard sizes like 2500×640 mm and 2500×1250 mm, or tailored to door panel dimensions.

- Efficient Application: Fleece backing on engineered veneers (as thin as 0.2 mm) eliminates the need for cutting or splicing, reducing material waste.

Thickness options such as 0.4 mm and 0.5 mm are also popular for wood door manufacturers.

Fleece Backed Bamboo Veneer

Bamboo veneers are a type of reconstituted veneer. Due to the natural splitting between bamboo strips, raw bamboo veneers cannot be used without fleece backing.

Fleece backing supports bamboo veneers ranging from 0.25 mm to 0.6 mm in thickness, ensuring stability and preventing peeling. Common bamboo veneer sheet sizes are 2500×430 mm, but widths can be spliced up to 1260 mm.

Fleece Backed Veneer Rolls

Most wood veneer rolls for edge banding and profile wrapping are fleece-backed to enhance tension resistance, improve bonding, and prevent splitting.

Popular options include fleece-backed red oak, white oak, American walnut, and African species like sapeli, mahogany, and okoume. These are widely used for:

- Door trims

- Window casings

- Skirting boards

- Moldings

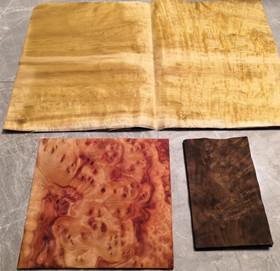

Rare Veneer With Fleece Backing

For rare and exotic wood veneers cut to ultra-thin sizes (0.1 mm–0.2 mm), fleece backing is essential to enhance flexibility and durability. Without this support, these delicate veneers are prone to breaking during handling and application.

Examples of Fleece-Backed Veneers

- Cross-Cut End Grain Veneers: End grain veneers, such as oak and ash, are particularly fragile and prone to splitting. Fleece backing provides the necessary support to prevent cracking during use.

- End Grain Walnut Veneer: Walnut end grain veneer is more stable than ash or oak, but fleece backing is still recommended to ensure durability and flexibility.

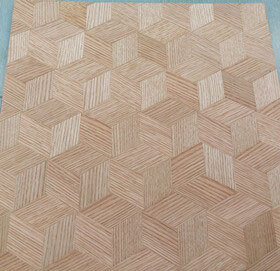

- Woven Veneers: Veneers with woven patterns benefit significantly from a hot-pressed fleece backing, which stabilizes the woven structure and prevents deformation.

- Matching Veneer Layons: Matching layons often require fleece backing to ensure consistency and structural integrity, particularly in intricate designs.

By adding fleece backing, these veneers become durable, flexible, and practical for various applications. This process ensures that even the most delicate and exotic veneer types can be used effectively in furniture, doors, and decorative projects.

20 Related Fleece Backed Wood Veneer Products

Fleece Backed Walnut Veneer

Fleece Backed Grey Veneer

Fleece Backed Dyed Veneer

Walnut Veneer Edge Banding

Fleece Backed Oak Veneer

UV Prefinished Edge Banding

Fleece Recon Walnut Veneer

Oak End Grain Edging

Cross Cut Walnut Veneer

Fleece Backed Maple Veneer

White Veneer Edge Banding

Fleece Back Woven Veneer

Fleece Back Wrapping Veneer

Fleece Back Bamboo Veneer

Fleece Back Mahogany Veneer

Fleece Back Burl Veneer

End Grain Oak Veneer

Fleece EV Walnut Veneer

End Grain Oak Veneer

Fleece Back Matching Veneer

Today, fleece-backed veneers are primarily produced as natural veneers and engineered veneers to meet growing demand.

Key Advantages of Fleece Veneers

- Common Thickness: Most fleece veneers are produced in 0.2 mm sheets, making them cost-effective compared to thicker veneers.

- Competitive Pricing: Thin fleece veneers are economical while still offering durability and flexibility.

Applications of Fleece-Backed Veneers

Fleece-backed veneers are widely used as surface layers on materials like:

- Plywood, MDF (Medium-Density Fiberboard), Particleboard

These veneers are perfect for manufacturing:

- Wood Doors, Cabinets, Furniture, Wall Coverings

Additionally, veneer rolls with fleece backing are ideal for:

- Edge Sealing: Provides clean, finished edges on plywood and furniture.

- Profile Wrapping: Ensures smooth coverage on curved or intricate surfaces like moldings and trims.

Frequently Asked Questions (FAQs)

What types of fleece backed veneers are available?

There are three main types: natural veneer, engineered veneer, and bamboo veneer. Any wood species can be backed with fleece.

How thin or thick should fleece-backed veneers be?

Fleece backing is recommended for veneers, ranging from 0.15 mm to 0.25 mm for stability. Some buyers request thicker veneers (up to 0.5 mm) for specific applications.

What are the specifications for fleece veneer sheets?

Our press machines can produce sheets up to 3100 mm in length and 1400 mm in width. Veneer rolls can be up to 640 mm wide with unlimited lengths.

How is fleece-backed veneer applied?

Fleece-backed veneers are applied similarly to regular veneers, typically on plywood, MDF, particleboard, or block board.

How do you fix wrinkled veneer?

Fleece backing combined with hot pressing ensures wrinkle-free veneer sheets.

Why choose fleece veneer?

Fleece veneers allow better wood resource utilization, producing more surface coverage from the same amount of wood. They are also durable and flexible, making them ideal for intricate applications like molding profiles and door trims.

Where can I buy fleece backed veneers?

China is a leading market for fleece-backed veneers, offering options from 0.15 mm to 0.5 mm thickness in natural and engineered varieties.

Back to top: Fleece Backed Veneers