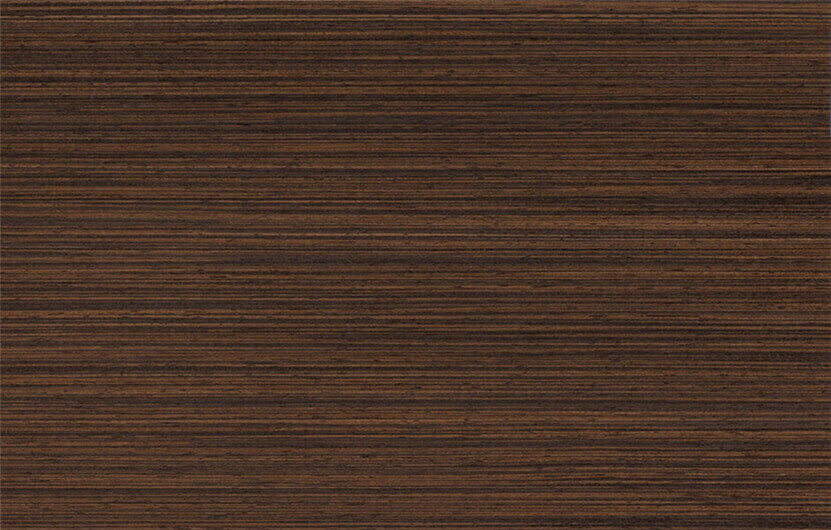

Artificial Veneer

Artificial veneer, also known as reconstituted wood veneer, composite wood veneer, man-made wood veneer, or engineered veneer, is a decorative hardwood veneer designed to replicate the look of natural wood.

It is made from fast-growing, renewable wood species such as Poplar, Ayous, and Basswood. The production process involves compressing and molding dyed wood veneers into different colors and patterns. This allows artificial veneer to maintain the natural beauty of wood while eliminating common defects found in solid wood.

Applications of Artificial Veneer

As an eco-friendly and sustainable alternative, artificial veneer is widely used in various industries, including:

- Furniture manufacturing

- Door skins

- Cabinets

- Engineered flooring

- Faced wood panels

- Wood profiles

- Hotel and interior decoration

Thanks to its consistent grain, uniform color, and defect-free surface, artificial veneer is an excellent choice for modern design and construction projects.

Key Features of Artificial Veneers

- Eco-Friendly – Our engineered veneer meets E0 grade environmental standards, with most products reaching E1 grade as a standard.

- High Color Fastness – Ensures long-lasting, vibrant colors that resist fading.

- Extensive Design Options – Choose from hundreds of patterns to match your style and project needs.

- Consistent Quality & Supply – We provide stable quality and reliable quantities for all orders.

- Higher Density & Smoother Surface – Reduces the need for excessive painting, saving you time and costs.

Available Dimensions

- Thickness: 0.2 mm – 3.0 mm

- Length: Standard 2500 mm, maximum up to 3400 mm

- Width: Standard 640 mm, maximum up to 1250 mm

Customization & Backing Options

- We offer OEM services, allowing you to customize veneer length, width, and thickness based on your needs.

- Available backing options:

- Original (raw veneer)

- Fleece-backed (non-woven fabric)

- Kraft paper-backed

For more details or custom requirements, feel free to contact us!

Back to top: Artificial Veneers