What is a Burl Veneer?

Burl veneer is a unique type of wood veneer crafted from burls—irregular growths that form on tree trunks or branches. These growths result in intricate, swirling patterns that give burl veneer its distinctive, artistic appeal. Often used for decorative purposes, burl veneer combines natural beauty with versatility, making it a favorite choice for furniture, paneling, and craft projects.

Burl veneer is typically 0.12 mm to 0.15 mm thick, and it can either be made from real natural burl wood or reconstituted burl designs. The face layer is bonded to the 10 mil kraft paper backing for added strength and stability.

This veneer is widely used in various applications such as hotel lobbies, cabinets, furniture, DIY woodworking projects, drum making, and interior decoration.

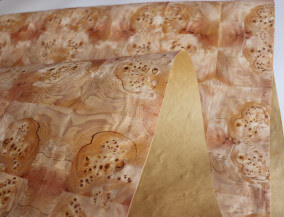

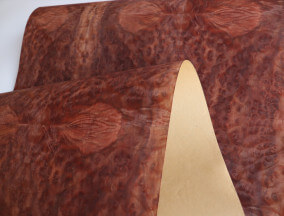

Natural Burl Veneer

Natural burl veneer is made from real burl wood, including types like Mappa burl, Walnut burl, Golden burl, Gold Nanmu burl, Camphor burl, and Fir burl. The process begins by slicing the burl wood into thin veneers, typically 0.12 mm to 0.15 mm thick, from the root wood.

Next, the sliced veneers are cut into rectangular pieces. Skilled workers then arrange the pieces on pre-glued paper, following the distinct patterns of the burl wood. Once arranged, the veneer is pressed using a cold press machine to ensure a durable and smooth finish.

The standard sheet size for natural burl veneer is 2500 x 610 mm (approximately 2 x 8 feet), with a final thickness of around 0.2 mm to 0.3 mm, including the paper backing.

Walnut Burl

Walnut Burl

Walnut Burl

Walnut Burl

Walnut Burl

Walnut Burl

Walnut Burl

Walnut Burl

Mappa Burl

Mappa Burl

Mappa Burl

Mappa Burl

Golden Burl

Golden Burl

Golden Burl

Golden Burl

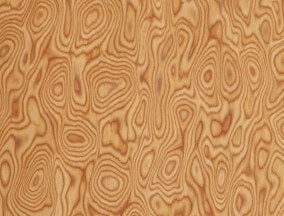

Fir Burl

Fir Burl

Fir Burl

Fir Burl

Camphor Burl

Camphor Burl

Camphor Burl

Camphor Burl

Gold Nanmu Burl

Gold Nanmu Burl

Gold Nanmu Burl

Gold Nanmu Burl

EV Oak burl

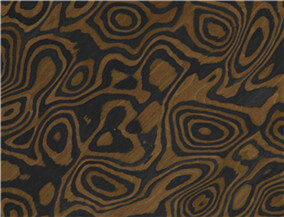

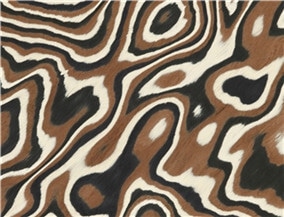

EV Ebony burl

EV Cherry burl

EV Leopard burl

Reconstituted Burl Veneer

Reconstituted burl veneers are engineered veneers that feature burlwood designs, such as oak burl, cherry burl, ebony burl, black burl, butterfly burl, and more. These veneers are created by combining natural burl patterns with sustainable materials to ensure consistent quality and design.

The standard sheet sizes for reconstituted burl veneer are 2500 x 640mm (2 x 8 ft) and 2500 x 1260mm (4 x 8 ft), with thicknesses ranging from 0.2mm to 0.9mm.

Unlike natural burl veneers, reconstituted burl veneer offers more consistent color and grain patterns, making it easier to match the surface of your entire project from sheet to sheet.

What Differentiates Burl Veneer from Regular Veneer?

The primary distinction lies in the appearance and formation. Regular veneer is cut from straight-grained wood sections, offering uniformity. Burl veneer, on the other hand, features complex, irregular patterns formed by the burl’s unique growth structure. This rarity and visual complexity make burl veneer more sought after and, in many cases, more expensive than standard veneers.

Common Uses for Burl Veneer

- Furniture Design: Adds elegance to tabletops, cabinets, and drawers.

- Automotive Interiors: Common in luxury cars for dashboard and trim detailing.

- Musical Instruments: Enhances the visual appeal of guitars, pianos, and other instruments.

- Craft Projects: Ideal for jewelry boxes, frames, and decorative inlays.

- Architectural Paneling: Adds sophistication to walls and ceilings.

How to Choose the Right Type of Burl Veneer?

- Wood Species: Select species like walnut, maple, or redwood depending on the desired appearance.

- Pattern Preferences: Look for specific patterns such as swirls, eyes, or feathering.

- Application Purpose: Ensure the veneer matches the project requirements in terms of durability and aesthetic.

- Finishing Options: Consider the compatibility of finishes like stains, oils, or lacquers.

What are the Different Grades of Walnut Burl Veneer?

Walnut burl veneer typically comes in three grades:

- A-Grade: Premium grade with minimal defects and high visual appeal.

- B-Grade: Includes minor imperfections but still offers striking patterns.

- C-Grade: Best suited for projects where aesthetic perfection is less critical.

What are Some Tips for Working with Burl Veneer?

Working with burl veneer requires careful handling and specific techniques to achieve the best results. Here are some tips to ensure a smooth process:

- Use a Veneer Saw: For precise cuts without tearing.

- Condition the Veneer: Use a veneer softener for improved flexibility.

- Work on a Flat Surface: Ensures proper adhesion during application.

- Protect with Finish: Seal the veneer to enhance durability and appearance.

What are the Common DIY Projects Using Burl Veneer?

Burl veneer can elevate a variety of DIY projects, adding a touch of luxury and craftsmanship. Some popular applications include:

- Accent Tables

- Custom Wall Art

- Refinished Drawer Fronts

- Decorative Boxes

How to Incorporate Burl Veneer in Home Decor?

Burl veneer is a versatile material that can add elegance and texture to various elements of home decor. Here are some ideas for incorporating burl veneer into your living spaces:

- Accent Walls: Install burl veneer panels for a dramatic effect.

- Furniture Accents: Use on cabinet doors or side table tops.

- Artistic Touches: Frame burl veneer for unique wall art.

- Kitchen and Dining Areas: Enhance countertops and dining tables with burl veneer inlays.

Burl Veneer Sheets FAQs

Can burl veneer be sanded?

Yes, but use light sanding to avoid thinning the veneer.

How is burl veneer applied?

It is typically glued to a substrate like plywood or MDF.

Can I stain burl veneer?

Yes, but test on a small area first to ensure desired results.

Can burl veneer be bent or curved?

Yes, burl veneer is flexible and can be bent over curves, but it should be softened with a veneer softener or steamed before bending.

How should I store burl veneer?

Store burl veneer flat in a cool, dry area, away from direct sunlight or humidity, to prevent warping or damage.

Is burl veneer durable?

Yes, burl veneer is durable when properly applied and finished, but it is thin and can be vulnerable to scratches and dents without a protective finish.

Back to top: Burl Veneer