Veneer core plywood is a type of engineered wood product that consists of thin layers of wood, or veneers, bonded together to create a strong and stable panel. This construction method enhances the plywood’s strength and resistance to warping, which makes it an ideal choice for various applications in furniture and cabinetry.

At WoodenAve, we are highly skilled in providing high-quality wood veneer solutions that cater to both residential and commercial needs.

Key Takeaways

- Veneer core plywood is made from multiple layers of wood veneers bonded together.

- It offers superior strength and stability compared to other core types like particleboard.

- Common applications include furniture manufacturing, cabinetry, and interior paneling.

- This plywood is relatively lightweight while maintaining excellent screw-holding capability.

What is Veneer Core Plywood?

Veneer core plywood, often referred to as VC plywood, is an engineered wood product crafted from thin sheets of wood called veneers. These veneers are bonded together with their grain in alternating directions for enhanced strength and dimensional stability.

The core veneer typically consists of multiple layers of these veneers, which provide a robust structure compared to solid wood. This type of plywood is particularly valued in the woodworking industry for its superior performance characteristics, making it a preferred choice for furniture makers and interior designers alike.

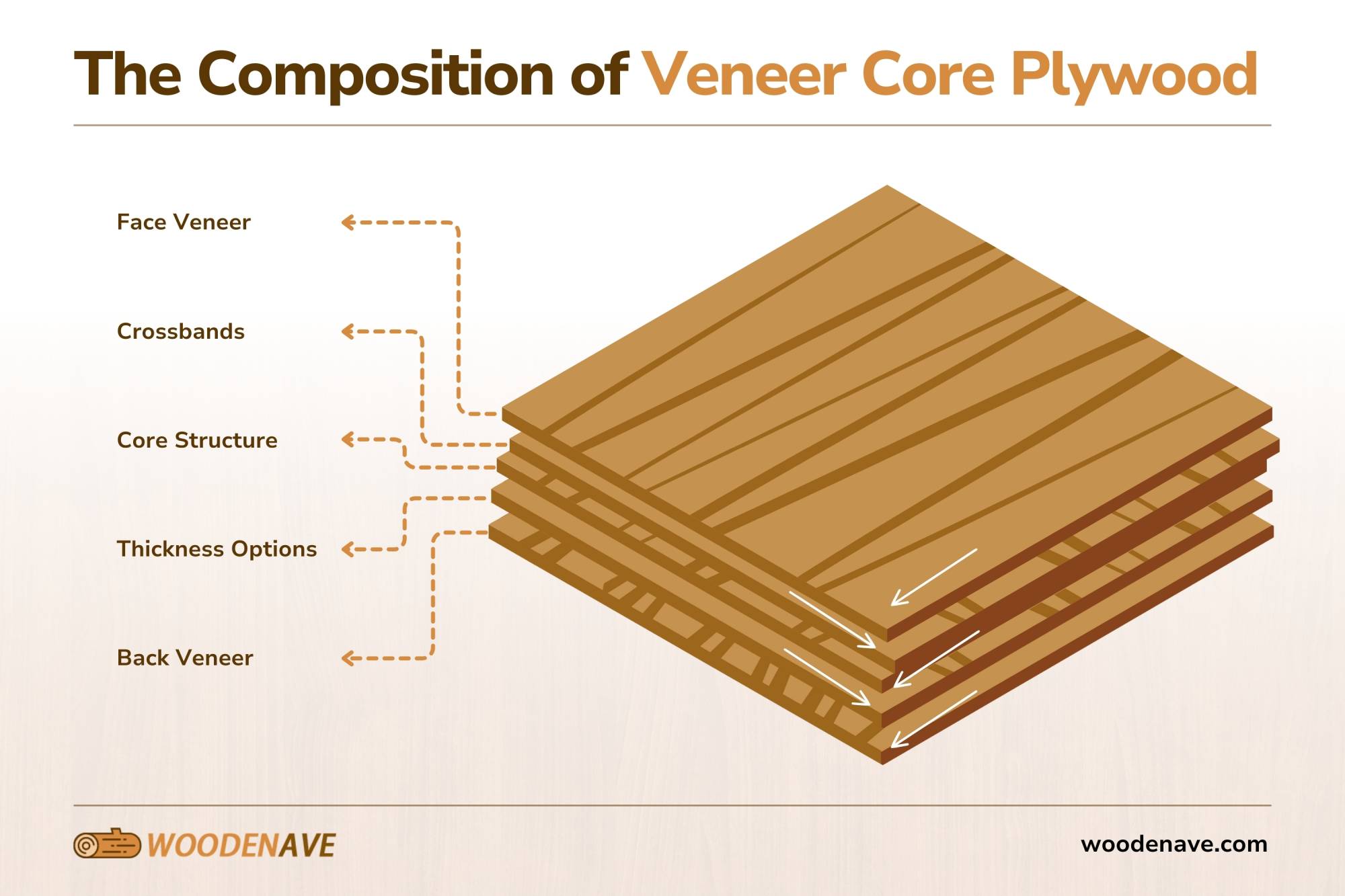

The Composition of Veneer Core Plywood

The composition of veneer core plywood includes several key elements, such as core structure, face and back veneers, crossbands, and thickness options. Below is the composition that contributes to its strength and durability:

- Core Structure: The core is constructed from layers of inner plies that are bonded together. This layered construction provides excellent dimensional stability and resistance to warping.

- Face and Back Veneers: The outer layers, known as face veneer and back veneer, are typically made from high-quality hardwood species such as birch or poplar. These veneers not only enhance the aesthetic appeal but also contribute to the overall strength of the panel.

- Crossbands: Many veneer core panels use crossbands — thin layers placed between the face veneer and the inner plies — to further improve stability and reduce the risk of core telegraphing.

- Thickness Options: Veneer core plywood is available in various thicknesses, allowing for flexibility in design and application.

This thoughtful composition ensures that veneer core plywood maintains its integrity under stress while providing a beautiful surface for finishing. However, there is a much more thorough process for how wood veneer is made.

Types of Veneer Core Plywood

Veneer core plywood types range from durable hardwood veneer cores with balanced durability and aesthetics to solid lumber cores perfect for cabinets, and smooth MDF cores with reduced screw-holding capacity. Composite and birch veneer cores add cost-effective utility or refined elegance for high-quality furniture, respectively.

| Type | Description |

|---|---|

| Standard Veneer Core | Hardwood veneers with alternating grain; balanced strength and aesthetics |

| Lumber Core Plywood | Solid lumber strips core; improved screw-holding, ideal for high-end cabinetry |

| MDF Core Plywood | Medium-density fiberboard core; smooth surface, lower screw-holding capacity |

| Composite Core Panels | MDF or particleboard core with veneer layers; cost-effective, less durable |

| Birch Veneer Core Blank | Fine grain, light color; used in high-quality furniture for superior appearance |

Several plywood core types are available: standard veneer core, lumber core plywood, MDF core plywood, composite core panels, and birch veneer core blank. Each of these is designed for specific applications and performance characteristics:

- Standard Veneer Core: This type features hardwood veneers bonded with alternating grain directions. It offers a good balance of strength and aesthetic appeal.

- Lumber Core Plywood: Made with solid lumber strips as its inner core, this option provides enhanced screw-holding capacity and is often used in high-end cabinetry.

- MDF Core Plywood: Incorporating medium-density fiberboard (MDF) into the core structure, this type offers a smooth surface but may have lower screw-holding capabilities compared to solid lumber cores.

- Composite Core Panels: These panels combine materials such as MDF or particleboard with veneer layers, offering cost-effective options while sacrificing some strength and durability.

- Birch Veneer Core Blank: Known for its fine grain and light color, birch is commonly used in high-quality furniture applications where appearance matters.

Each type has its unique advantages depending on the intended use, making it essential for designers and builders to choose the right option based on their specific needs.

Applications of Veneer Core Plywood

Veneer core plywood finds extensive use across various industries due to its versatility, including furniture, interior paneling, architecture, and musical instruments:

- Furniture Manufacturing: Its strength-to-weight ratio makes it ideal for cabinets, tables, and shelving units where aesthetics and durability are crucial.

- Interior Paneling: Used in wall coverings and decorative panels, veneer core plywood provides an attractive finish while maintaining structural integrity.

- Architectural Applications: In commercial settings, VC plywood is often used for doors and partitions due to its lightweight nature combined with excellent bending strength.

- Musical Instruments: High-quality plywood is frequently used in crafting instruments like pianos, where sound quality depends on material properties.

These applications illustrate how veneer core plywood serves as a reliable material across diverse sectors.

Benefits of Veneer Core Plywood

Veneer core plywood offers numerous benefits that make it a top choice among builders and designers, such as strength, stability, lightweight nature, screw-holding capacity, aesthetics, and affordability:

- Strength and Stability: The multilayered construction provides exceptional bending strength and dimensional stability compared to other composite materials like particleboard or MDF.

- Lightweight Nature: Despite its strength, veneer core panels are relatively light in comparison with composite options, making them easier to handle during installation.

- Impressive Screw Holding Capability: The alternating grain structure enhances screw holding ability, which allows for secure fastening without splitting or damage.

- Aesthetic Versatility: With various species of veneer available — including softwood and hardwood — this plywood can be tailored to meet specific design requirements.

- Cost-Effective Option: While it may be more expensive than particleboard options initially, its durability often results in lower long-term costs due to reduced maintenance needs.

These benefits underscore why many professionals choose veneer core plywood over alternative materials.

WoodenAve: Affordable Wood Veneer

Veneer core plywood stands out as an exceptional material for various woodworking projects due to its unique properties and versatility. At WoodenAve, we offer affordable wood veneer solutions tailored to meet your specific needs.

Whether you’re looking for high-quality panels for furniture or cabinetry, our selection ensures you find exactly what you need at competitive prices. Explore our range of wood veneers today!

Back to Top: What is Laminated Veneer Lumber?

FAQs on What is Veneer Core Plywood?

Is veneer core plywood the best?

Veneer core plywood is a great choice for applications requiring high strength, flatness, and durability. However, depending on the project, other plywood core options like particleboard core may be more suitable for cost-sensitive or lightweight uses.

What is the difference between classic core and veneer core?

Classic core plywood typically uses a solid wood core, while veneer core plywood features thin layers of wood veneers, providing better strength and stability. Veneer core hardwood plywood is more resistant to warping and offers a smoother surface.

What is the difference between armor core and veneer core?

Armor core is a reinforced plywood core, offering extra durability and impact resistance, often used in high-traffic areas. Veneer core offers superior strength and flatness, making it ideal for high-quality grade plywood used in cabinetry and furniture.

Back to Top: What is Veneer Core Plywood?