The main difference between veneer and laminate lies in their materials: veneer is a thin layer of real wood, while laminate is a synthetic product designed to mimic the appearance of wood. Understanding these differences is crucial for selecting the right material for your furniture or cabinetry.

At WoodenAve, we are experienced in providing high-quality wood veneer products that improve the beauty and functionality of your spaces. Let’s break down the differences between laminate and veneer!

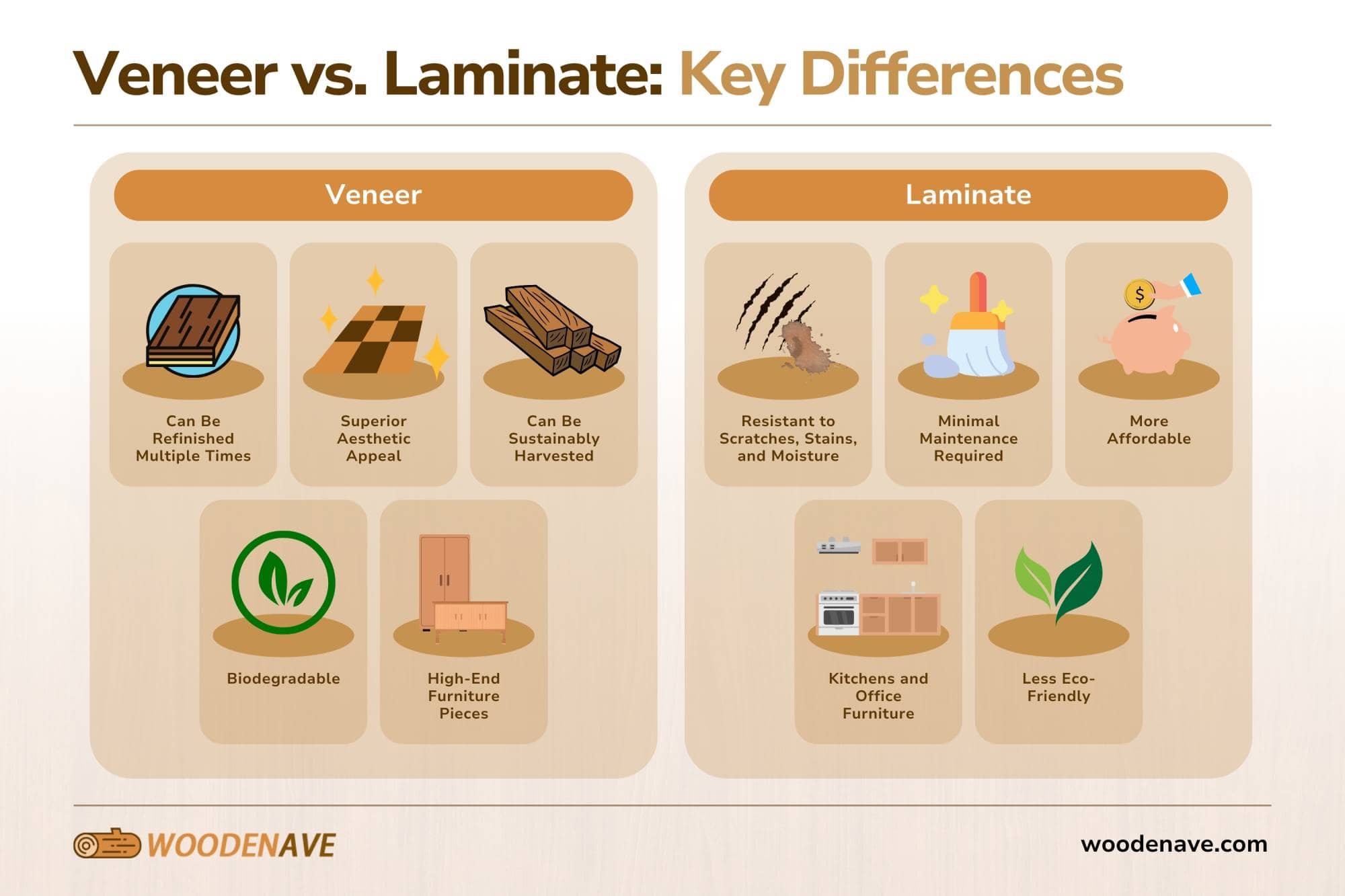

Key Takeaways

- Veneer is a thin layer of real wood, while laminate is a synthetic material designed to look like wood.

- Veneer offers unique grain patterns and can be stained, whereas laminate provides a uniform appearance.

- Laminate is generally more durable and resistant to scratches compared to veneer.

- Cost-wise, laminate is usually less expensive than veneer, making it a budget-friendly option.

- Environmental impact favors veneer, as it is made from natural materials and can be refinished.

Veneer vs. Laminate

Veneer offers the unmatched elegance of real wood, with its unique grain and natural depth, ideal for premium furniture, but demands higher care and cost. In comparison, laminate, a budget-friendly alternative, mimics wood’s appearance with resilience against wear and tear, making it perfect for practical, low-maintenance applications.

| Aspect | Veneer | Laminate |

|---|---|---|

| Definition | Thin real wood layer on plywood or MDF | Paper and resin layers mimicking wood |

| Composition | Real wood with unique grain patterns | Printed wood grain on paper, coated in resin |

| Manufacturing | Sliced wood adhered to substrate | Paper layers fused with resin |

| Aesthetic Appeal | Authentic, natural look with depth | Uniform, less tactile, but wood-like |

| Durability | Susceptible to damage; refinishable | Scratch- and moisture-resistant; low-maintenance |

| Cost | More expensive due to real wood | More affordable; mass-produced |

| Environmental | Biodegradable; sustainable if responsibly sourced | Less eco-friendly — made with resins and plastics |

| Applications | High-end furniture and cabinetry | Practical uses like kitchen cabinets, office furniture |

When comparing veneer and laminate, it’s essential to understand their definitions, compositions, manufacturing processes, aesthetic appeals, durability, cost differences, environmental impacts, and applications.

Definition

Veneer refers to a thin layer of real wood that is sliced from a log and applied to a substrate, like plywood or medium-density fiberboard (MDF). This allows the beauty of natural wood to be showcased without the need for solid wood pieces.

In contrast, laminate is made from layers of paper and resin that are bonded together under heat and pressure to create a durable surface that mimics the look of wood. According to National Business Furniture, real wood, wood veneer, and laminate are the top three most popular materials used in furniture.

Composition

Veneer consists of real wood sourced from various species such as oak, cherry, or walnut. This composition ensures that each piece has unique characteristics and grain patterns.

On the other hand, laminate is primarily made from paper that has been printed with a wood grain design and coated with resin for durability. While laminate can imitate the appearance of different types of wood, it lacks the authenticity and depth found in real wood veneers.

Manufacturing Processes

The manufacturing process for veneer involves slicing or peeling logs into thin sheets. These sheets are then fitted to substrates like plywood or MDF using adhesives. This method preserves the natural beauty of the wood while allowing for versatile applications in furniture crafting.

The production of laminate involves creating layers of paper that are impregnated with melamine resin. These layers are then fused under high pressure to form a solid sheet that resembles wood. This process allows for mass production and consistency in design but sacrifices the uniqueness found in natural wood. However, you also get laminate wood veneer!

Aesthetic Appeal

Veneer offers an authentic look with its rich textures and unique grain patterns that vary from piece to piece. This natural beauty can be enhanced with stains or finishes that highlight the wood’s characteristics. The result is furniture that exudes warmth and elegance.

Laminate products provide a uniform appearance with less variation since they are manufactured in bulk. While modern laminates can closely resemble real wood — thanks to advanced printing technologies — they often lack the depth and tactile quality of genuine veneer surfaces. For those seeking an authentic aesthetic in their furniture or cabinetry, opting for veneer is typically preferred.

Durability and Maintenance

When it comes to durability, laminate outperforms veneer in many aspects. Laminate surfaces are resistant to scratches, stains, and moisture, making them ideal for high-traffic areas like kitchens or offices, where wear and tear are common. They require minimal maintenance — generally just a damp cloth for cleaning.

Veneer surfaces can be more susceptible to damage from moisture or heavy impacts.

However, they can be sanded down and refinished if scratched or worn over time. Regular maintenance involves polishing with appropriate products to protect the veneer finish and enhance its longevity. One of the most common maintenance issues is how to fix bubbled wood veneer, but it just takes a bit of patience!

Cost Differences

Generally speaking, laminate is less expensive than veneer due to its synthetic nature and mass production capabilities. This makes laminate an attractive option for budget-conscious consumers looking for affordable furniture solutions.

Veneer tends to be more expensive than laminate because it uses real wood materials and requires skilled craftsmanship during production. However, many consider this investment worthwhile due to its aesthetic appeal and potential longevity when properly maintained.

Environmental Impact

From an environmental perspective, veneer has advantages over laminate. Veneers are derived from natural wood sources and can be sustainably harvested if sourced responsibly. They are biodegradable and can be refinished multiple times throughout their lifespan.

Laminates are made from resins and plastics that do not decompose easily. The production process also involves chemicals that can have environmental implications. For eco-conscious consumers looking for sustainable options in their home furnishings, opting for high-quality veneer products is often the better choice.

Applications

Veneer is commonly used in high-end furniture pieces such as dining tables, cabinets, and decorative devices where aesthetic appeal is paramount. Its versatility allows veneer to be applied in various settings — from residential homes to commercial spaces.

Laminate finds its place in practical applications such as kitchen cabinets, office furniture, and other areas where durability is crucial. Its resistance to moisture makes it particularly suitable for environments prone to spills or heavy use.

WoodenAve: Custom Wood Veneer Solutions

Understanding the differences between veneer and laminate can help you make informed choices about your furniture needs. Whether you prefer the authentic beauty of real wood or the practicality of synthetic materials depends on your specific requirements.

At WoodenAve, we offer custom wood veneer solutions tailored to enhance your space with elegance and durability while showcasing the true beauty of natural wood. Explore our collection today!

FAQs on Veneer vs. Laminate: Key Differences and Which to Choose

What is laminated veneer lumber vs. glulam?

Laminated Veneer Lumber (LVL) is made by bonding thin layers of wood veneers, which offers superior strength and dimensional stability. Glulam, or glued laminated timber, uses thicker laminations to create structural beams. While both are engineered wood, LVL is often preferred for smaller, more precise applications like I-joists.

What is veneer finish?

A veneer finish is a thin layer of wood applied to a substrate to give the appearance of solid wood without the cost. It is typically used on wood furniture to achieve a high-end look while using less expensive material, like particleboard or MDF.

What is the main disadvantage of veneer finish?

The main disadvantage of a veneer finish is its susceptibility to damage, as the thin layer of wood can be scratched or chipped more easily than solid wood. Additionally, veneer furniture may not have the same longevity or feel like real wood in some cases.