Acoustic panels are made of sound-absorbing materials like wood, foam, or fabric. These panels reduce echo and improve sound quality in rooms and work by trapping sound waves in their porous structure. Acoustic panels come in various sizes, shapes, and materials. Used in homes, offices, and studios, acoustic panels can control sound and are often mounted on walls or ceilings for the best results. WoodenAve offers high-quality wooden acoustic panels for optimal sound control in any space.

Key Takeaways

- Acoustic panels absorb sound waves to reduce echo.

- Wood, foam, and fabric are common materials for acoustic panels.

- Panel effectiveness depends on material, size, and placement.

- Wooden panels offer both acoustic benefits and aesthetic appeal.

- Proper installation is essential for optimal sound absorption.

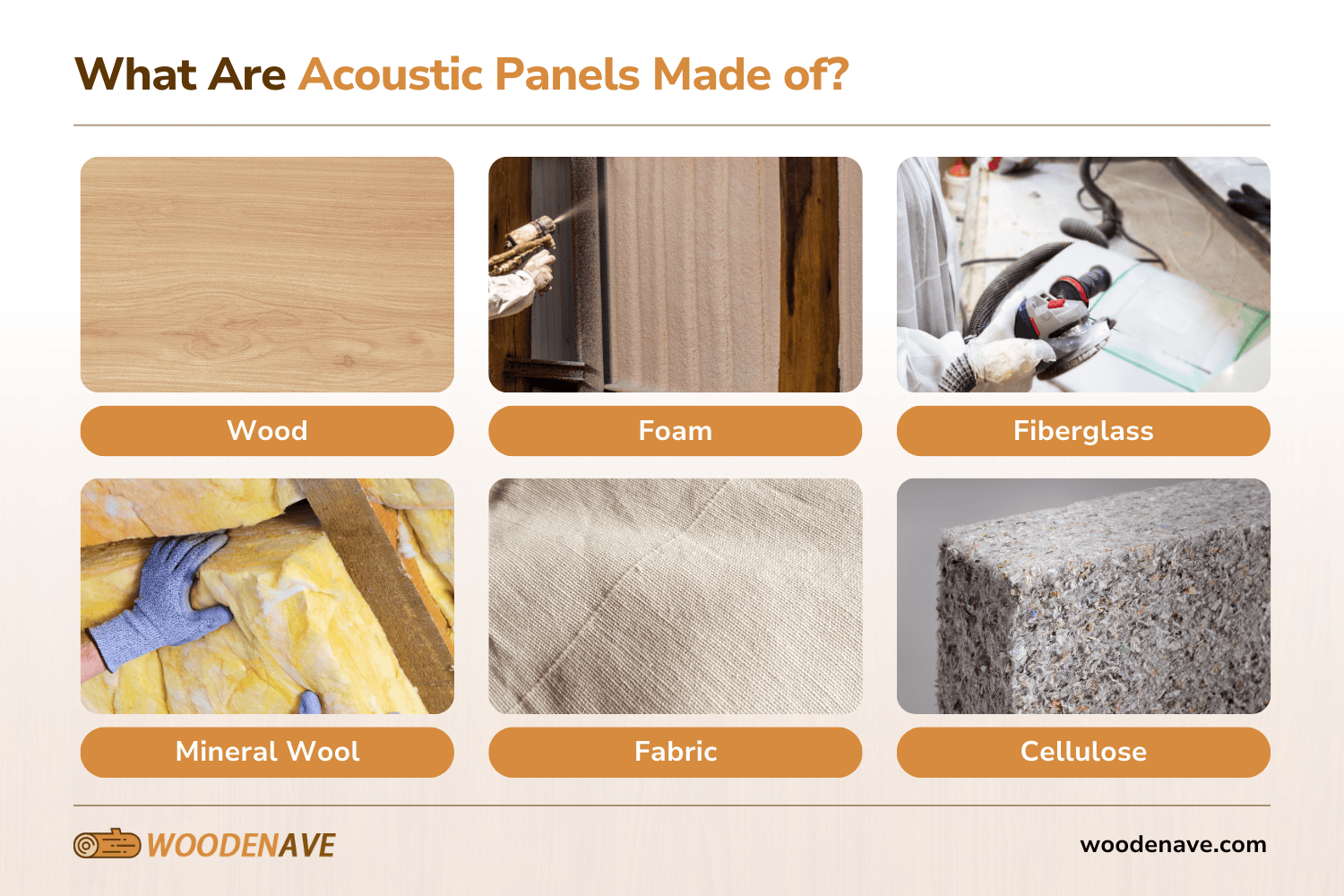

What are Acoustic Panels Made of?

Acoustic panels are made of various sound-absorbing materials. Common materials include wood, fabric, and foam:

- Wood: Wood panels often have a core of porous material covered with wood veneer. This combination provides both sound absorption and visual appeal.

- Foam: Foam panels are lightweight and highly absorbent, which makes them popular for DIY projects.

- Fiberglass: Fiberglass offers excellent sound absorption properties, especially for low frequencies.

- Mineral wool: Mineral wool, like fiberglass, provides great sound absorption for low frequencies.

- Fabric: Fabric panels combine aesthetics with functionality, allowing for customizable designs.

- Cellulose: Cellulose panels are eco-friendly options made from recycled paper, appealing to environmentally conscious consumers.

The choice of material affects the panel’s performance and appearance. Some panels use a mix of materials to balance acoustics and aesthetics. The panels’ internal structure can vary, with some using perforations or slats to enhance sound absorption.

Are Acoustic Panels Effective?

Yes, acoustic panels are effective at improving room acoustics. They work by absorbing sound waves that would otherwise bounce off hard surfaces, which reduces echo and reverberation in a space. The effectiveness of acoustic panels depends on several factors:

- Material composition

- Panel thickness

- Surface area covered

- Placement in the room

Properly installed acoustic panels can significantly improve sound quality. They help create a balanced acoustic environment, which is useful in recording studios, conference rooms, and home theaters. Panels can target specific frequency ranges based on their design and material.

Acoustic panels also help with sound isolation and reduce noise transfer between rooms. They improve speech intelligibility in lecture halls and classrooms. In music venues, panels improve the listening experience by controlling reflections. The effectiveness of panels is often measured using the Noise Reduction Coefficient (NRC) rating. According to a study by Personnel Today, approximately 65% of workers say that their ability to work efficiently is interrupted by noise at work. This is another reason why acoustic panels are so important!

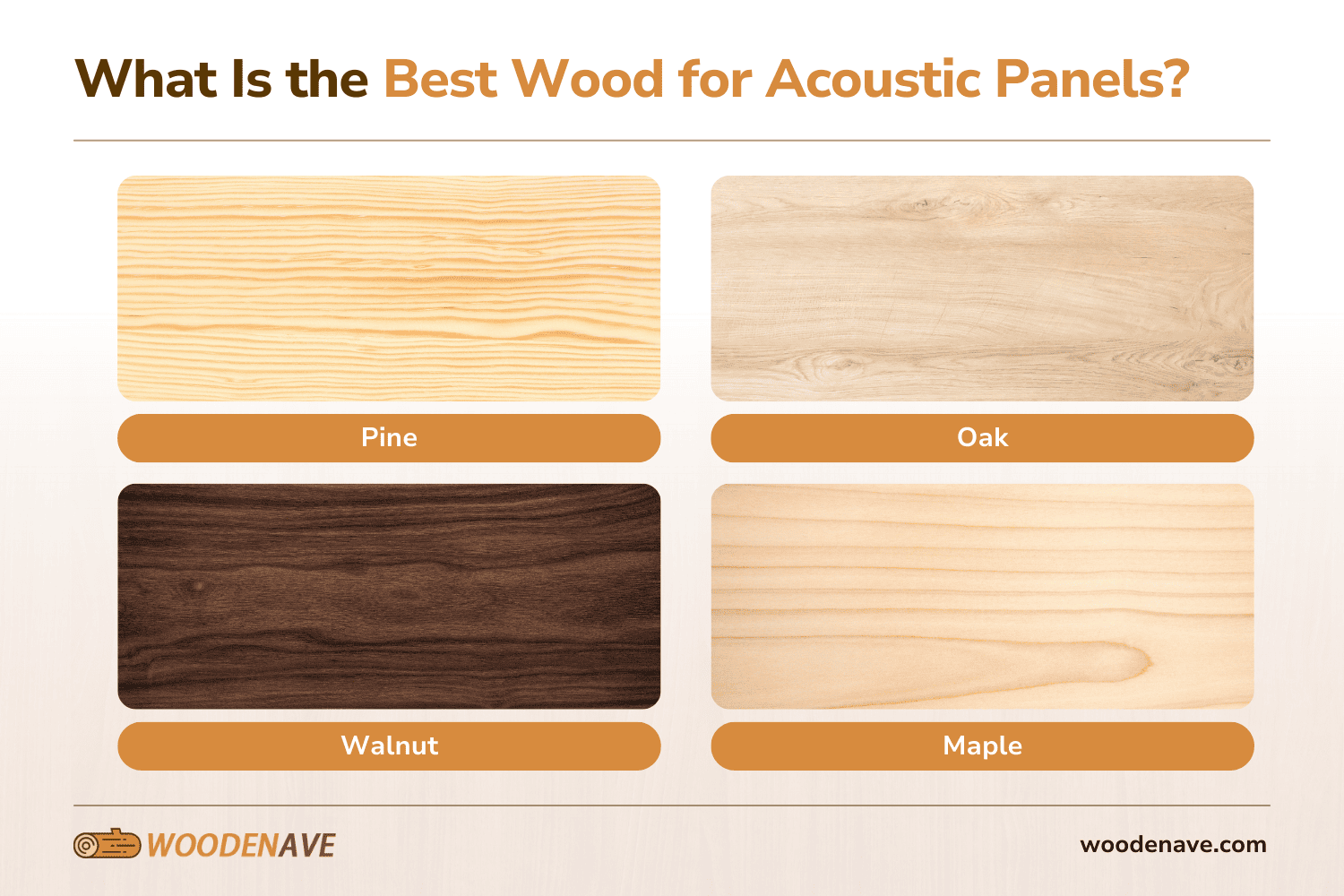

What is the Best Wood for Acoustic Panels?

The best wood for acoustic panels depends on specific needs and preferences, but popular options include pine and oak. Here are the best wood options:

| Wood Type | Sound Absorption | Aesthetics | Cost |

| Pine | Good | Rustic | Low |

| Oak | Very Good | Classic | Medium |

| Walnut | Excellent | Luxurious | High |

| Maple | Good | Modern | Medium |

The best wood for acoustic panels often balances acoustic properties with visual appeal. Some panels use a combination of wood for optimal performance and aesthetics. Hardwoods like oak and walnut tend to offer better durability and sound absorption. In contrast, softwoods like pine are more budget-friendly and easier to shape.

Wood panels can be finished with veneers or stains to match the decor. Some manufacturers offer exotic wood options for unique looks. The grain pattern of wood can affect both acoustics and appearance. Moreover, engineered wood products are also used in some acoustic panels.

Acoustic Wood Panel Size

Acoustic wood panel sizes vary based on application and room requirements, but the standard size is 24″ x 24″. Common sizes include:

- 24″ x 24″ (standard size)

- 24″ x 48″

- 12″ x 48″

- Custom sizes

Larger panels generally offer better low-frequency absorption, whereas smaller panels are more versatile for targeted treatment. The ideal size depends on:

- Room dimensions

- Problem frequencies

- Available wall space

- Aesthetic preferences

Panel thickness also affects performance. Thicker panels absorb a wider range of frequencies. Most acoustic wood panels range from 1 to 4 inches thick. Some manufacturers offer modular systems for flexible sizing options.

The size of panels can impact installation methods and costs. Larger panels may require additional support, while smaller panels allow for more creative arrangement patterns. Custom sizes can be ordered for specific project needs.

How to Install Acoustic Wooden Sound Panels: Step-by-Step Guide

To install acoustic wooden sound panels, start by measuring the room and installing the brackets. Here’s a step-by-step guide:

- Measure the room and plan panel placement

- Mark installation points on the wall

- Install mounting brackets or furring strips

- Apply adhesive to the back of the panel (if needed)

- Carefully position the panel on the wall

- Secure the panel using screws or mounting clips

- Repeat for remaining panels

- Check all panels for secure attachment

You must ensure proper spacing between panels for optimal sound diffusion. Moreover, clean the installation area thoroughly before mounting panels. Follow manufacturer guidelines for the best results. It would also be a good idea to consider professional installation for complex setups. And, remember to use a level to make sure panels are straight and aligned.

Safety is important during installation, so always wear protective gear and use proper tools. Some panels may require special handling because of their weight or fragility. Consider acoustic treatment behind panels for enhanced performance.

WoodenAve: Premium Wood Veneer and Wood Sound Panels

WoodenAve offers top-quality wood veneer and sound panels; our products combine acoustic performance with stunning aesthetics. We provide custom solutions for any space, and our panels are made from sustainably sourced wood materials.

We also offer a range of finishes to match any interior design style. Our team can help with panel selection and installation planning. Contact us today to improve your room’s acoustics with our premium wooden panels.

What Are Acoustic Panels Made of? | FAQs

What is the difference between acoustic panels and absorption?

Acoustic panels control sound energy by reducing echoes and dampening sound in spaces. In contrast, sound absorption refers to the process where sound-absorbing material soaks up sound waves. Panels like wood acoustic panels help with both soundproofing and improving clarity. Acoustic ceiling treatments and slat wall designs also contribute to sound management.

What are the disadvantages of acoustic wall panels?

Some disadvantages of acoustic wall wood panels include that they can be expensive and may not fully block out noise. Some soundproofing wood panels require thick sound absorption material for effectiveness. Wood panel dimensions affect performance, and improper sizing reduces efficiency. While woodpanels improve acoustics, they may alter room aesthetics or require maintenance.

Do I need professional installation for acoustic wood panels?

It’s not necessary but definitely advised. Professional installation ensures acoustic wood wall panels work effectively for sound absorption. DIY installation risks improper placement, which can reduce the impact of the sound absorber. Wood panel soundproofing requires correct alignment to function successfully. If unsure, hiring experts guarantees optimal wood panel sound absorption results.