Oak veneer is a thin layer of oak wood applied to surfaces to provide the appearance of solid oak without the associated costs of using solid oak. This versatile material is widely used in furniture making and interior design, offering the beauty of oak while being more affordable and environmentally friendly.

At WoodenAve, we specialise in high-quality real wood veneer products and ensure you have access to the best materials for your projects. In this article, we’ll examine what are oak veneers, the differences between oak and oak veneer, and more!

Key Takeaways

- Oak veneer is a thin layer of wood that mimics solid oak.

- It is available in various types, including white oak and red oak.

- The manufacturing process involves cutting, drying, and quality control.

- Oak veneer is used in furniture, cabinetry, and interior design applications.

- This veneer offers durability and aesthetic appeal at a lower cost than solid wood.

Oak Veneer Meaning

Oak veneer refers to a thin slice of oak wood that is typically less than one-eighth of an inch thick (less than 3.175 cm). This veneer allows manufacturers to cover surfaces like medium-density fibreboard (MDF) or plywood with a beautiful oak finish. The primary advantage of using oak veneer is that it provides the luxurious look of solid oak while being more economical. This makes it an ideal choice for various applications, from furniture to cabinetry.

Main Types of Oak Veneer

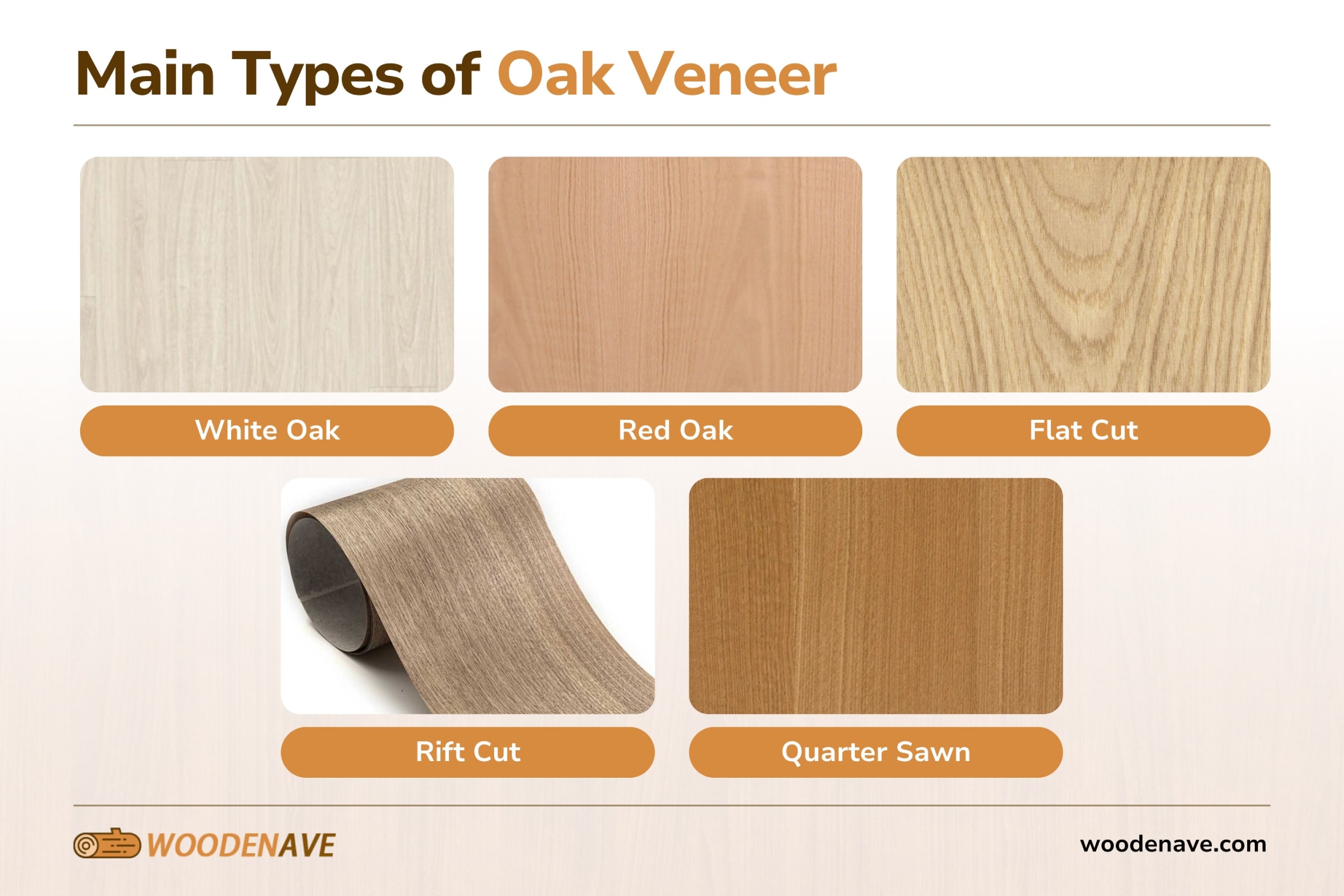

Oak veneers offer a stunning range of options, from the light, elegant grains of white oak to the warm, rustic charm of red oak. Choose flat cut for dramatic cathedral patterns, rift cut for sleek uniformity, or quarter sawn for exquisite ray flecks and superior stability. Here’s a look at the different types of oak veneer in detail:

| Type of Oak Veneer | Description |

|---|---|

| White Oak | Known for its light colour and prominent grain patterns; often used in traditional and modern furniture |

| Red Oak | Features a reddish hue with a pronounced grain; popular for rustic-style furniture |

| Flat Cut | Produces a cathedral grain pattern that showcases the natural beauty of the wood |

| Rift Cut | Offers a linear grain pattern, reducing flecking for a more uniform appearance |

| Quarter Sawn | Provides unique ray fleck patterns and increases stability — ideal for high-quality furniture |

These types of oak veneer allow designers and manufacturers to choose the right veneer based on aesthetic preferences and functional requirements.

The Oak Veneer Manufacturing Process

The manufacturing process of oak veneer involves several steps:

- Sourcing Logs: High-quality logs are selected based on species and desired characteristics.

- Preparation: Logs are debarked to remove the outer layer before being soaked or steamed to soften their fibres.

- Cutting: The logs are sliced using various techniques (flat cut, rift cut, quarter sawn) to achieve different grain patterns.

- Drying: The sliced veneers are air-dried or kiln-dried to ensure stability and prevent warping.

- Quality Control: Each batch goes through rigorous checks to maintain high standards before being packaged for distribution.

This meticulous process ensures that the final product meets quality expectations while showcasing the natural beauty of oak wood.

Oak Veneer Applications

Oak veneer is regularly used for furniture, interior design, and customised projects because of its aesthetic appeal and versatility:

- Furniture: Commonly applied to dining tables, coffee tables, dressers, and cabinets, providing an elegant finish

- Interior Design: Used in wall panelling and cabinetry, to enhance the overall look of residential and commercial spaces

- Custom Projects: Ideal for bespoke designs, allowing artisans to create unique pieces tailored to specific needs

Notably, as veneers can be used on different substrates like MDF or plywood, it’s easier for manufacturers to create high-quality products at lower costs.

Benefits of Oak Veneer

Oak veneer’s benefits include being cost-effective, durable, environmentally friendly, aesthetically appealing, and easy to maintain. Let’s review oak veneer’s advantages over solid wood in detail:

- Cost-Effective: Provides the look of solid wood without the high price tag associated with solid timber

- Durability: While not as durable as solid wood, quality oak veneer can withstand temperature changes and minor wear

- Environmentally Friendly: Uses less wood than solid pieces, making it a more sustainable option

- Aesthetic Appeal: Beautiful natural grain patterns enhance the visual appeal of any piece of furniture

- Easy Maintenance: Easier to repair than solid wood; minor scratches can often be sanded out without affecting the overall appearance

These benefits make oak veneer a popular choice among both manufacturers and consumers.

Oak Veneer vs. Solid Wood

When comparing oak veneer with solid wood, oak veneer offers a stylish, budget-friendly, and sustainable option, whereas solid wood delivers exceptional durability, unique character, and timeless appeal. Further, oak veneer is less durable and prone to peeling, while solid wood is pricier and has a greater environmental impact.

| Feature | Oak Veneer | Solid Wood |

|---|---|---|

| Cost | More affordable | Generally more expensive |

| Durability | Less durable; prone to peeling if damaged | Highly durable; withstands wear better |

| Aesthetic | Mimics solid wood appearance | Offers unique character with each piece |

| Maintenance | Easier to repair; can be refinished | Can be sanded and refinished multiple times |

| Environmental Impact | Uses less timber; more sustainable | Requires more resources |

Understanding these differences helps you make informed decisions about which material best suits your needs. Get in touch with us if you need help choosing between oak veneer and solid oak!

WoodenAve: Premium Oak Veneer

At WoodenAve, we provide premium oak veneer products that combine beauty with functionality. Our selection includes various types of oak veneers suitable for all woodworking projects. Whether you’re making furniture or refacing surfaces, our high-quality real wood veneer ensures you have everything you need to get started on your project. Explore our range of engineered veneers today and experience the superior quality that WoodenAve offers.

FAQs on What is Oak Veneer?

Is veneer real wood?

Yes, veneer is real wood made by slicing a thin piece of wood from natural logs, like cut red oak or flat-cut white oak. It highlights the wood grain of oak wood veneer while being more affordable than solid wood furniture. Common types of wood for veneer include hardwood like oak, used in oak doors, and high-quality real wood veneer products.

What are the disadvantages of oak veneer?

Oak veneer wood is less durable than solid oak furniture, as it may peel or chip over time. Unlike solid wood furniture, it cannot withstand heavy sanding or refinishing, making repairs difficult. Although its wood veneer sheets look like natural wood, oak veneer may lack the robust longevity of thicker hardwood.

Does oak veneer scratch easily?

Yes, oak wood veneer comes complete with a natural look but scratches more easily than solid oak furniture. While cut red oak wood veneer and other products display beautiful wood grain, they are thinner and less resistant to damage. Whether you choose wood or veneer, handling carefully can minimise wear on your oak doors or furniture.

Back to Top: What is Oak Veneer?