Wood veneer is essentially a thin layer of real wood that is sliced from logs. These thin slices of wood, usually less than 0.125 inches (3.175 mm) thick. Veneer wood is used to cover surfaces and create a pleasing, decorative finish. If you’re looking to expand the aesthetics of your space with a delightful finishing touch, then wood veneer is a great choice.

At WoodenAve, we understand how important your furniture choices are. We supply a wide range of quality wood veneer products to use for your special designs and arrangements. Wood veneers have a role to play in a variety of functions, from furniture and cabinetry to interior design and more!

Key Takeaways

- Wood veneers are a thin layer of wood sliced from logs.

- Veneers can be laminated onto thicker layers to build panels, such as doors.

- Wood veneers are typically used for furniture, cabinetry, and interior design.

- They are affordable, sustainable, versatile, stable, and aesthetically pleasing alternatives to solid wood.

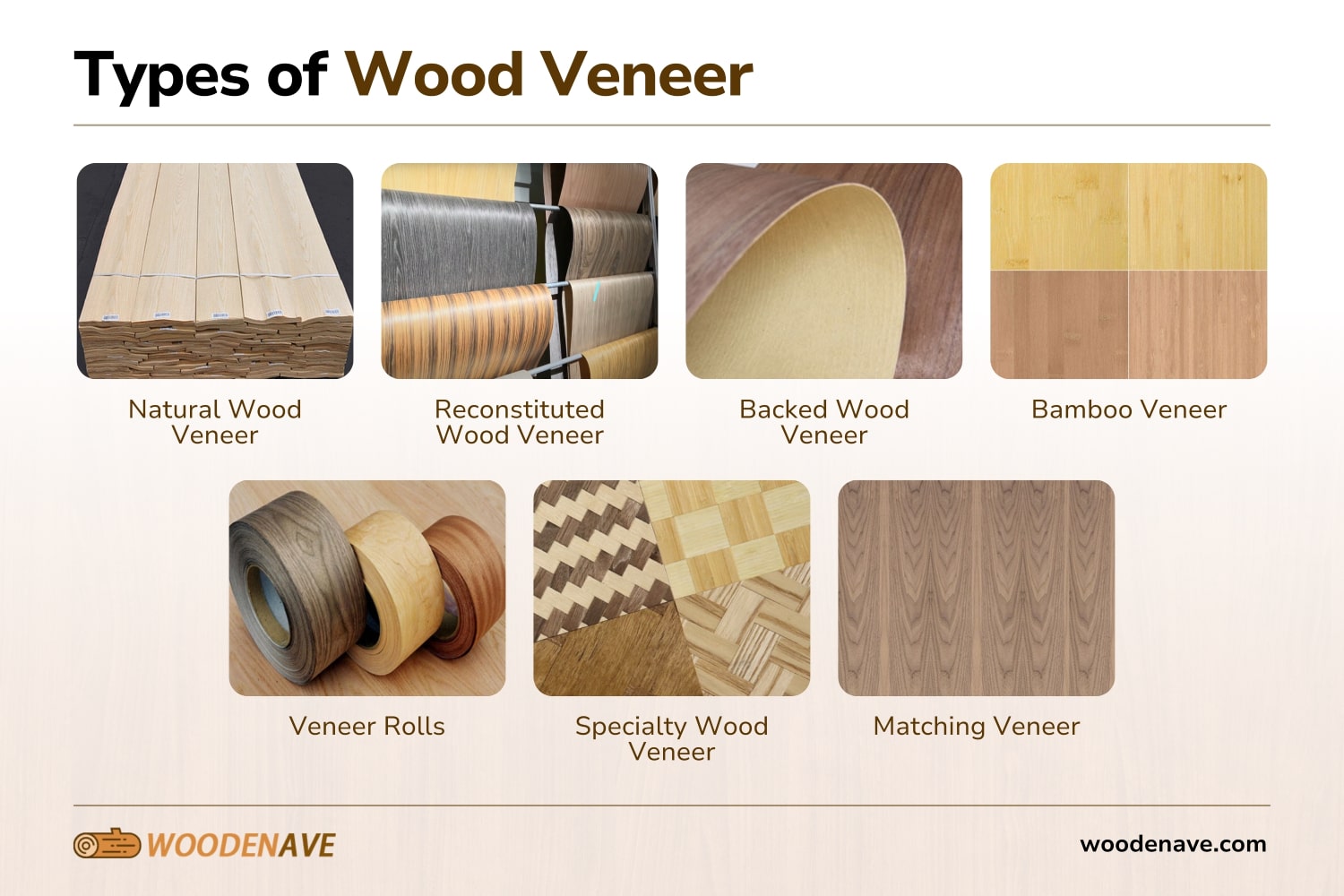

Types of Wood Veneer

It’s essential to pick the right type of wood veneer, so you don’t endanger the aesthetics and practicality of your space. These are the different types of wood veneers:

- Natural Wood Veneer is sliced directly from solid wood logs, often oak, maple, and mahogany.

- Reconstituted Wood Veneer is also known as engineered wood, composite base wood, or artificial wood. It’s made from fast-growing species or recycled fibers of wood.

- Backed Wood Veneer is reinforced veneer with a backer, such as phenolic or paper backed veneer, to improve its durability. It also makes for more flexible wood. This type of veneer works well for curved surfaces.

- Bamboo Veneer is made of laminated bamboo blocks that are thinly sliced into sheets to make bamboo veneer.

- Veneer Rolls are rolls of veneer sheets in multiple layers, designed to create thicker panels.

- Matching Veneer is usually used for door or panel layouts. Matching veneer is a jointed wood veneer sheet glued or threaded together to create various designs.

- Specialty Wood Veneer offers a more exotic look. It is made from processed wood veneer pieces that are cut and spliced into unique designs.

Common Applications of Wood Veneer

- Furniture: Wood veneers are often used for dining tables, tabletops, drawers, and shelves for a more sophisticated look and feel.

- Architectural Elements: Often, an architect will use veneers in wall panels, doors, and moldings for both residential and commercial areas as it creates a cohesive design. Additionally, you can do marquetry as part of your interior design, which is the art of applying veneer to a structure to create interesting patterns. It’s possible to dye veneers to blend into your designs, too.

- Cabinetry: Using wood veneers for cabinets is quite popular for kitchens and bathrooms. Wood veneers look seamless in these areas and have a modern appearance.

- DIY: DIY enthusiasts and homeowners often use wood veneers to enhance interiors designs.

- Commercial Use: Wood veneers are widely used by furniture manufacturers, interior designers, and contractors for residential and commercial projects.

Benefits of Using Wood Veneer

There are many advantages to using wood veneer in your space, from pricing to aesthetics. Let’s dive into a few of the many benefits:

- Affordable: One of the greatest benefits of high-quality veneers is that they look just like solid wood, but they cost a fraction of the price. That means you can use expensive variations of wood species without worrying about cutting too deep into your budget.

- Sustainable: As the manufacturing process of wood veneers uses less wood than solid wood, it’s a much more environmentally friendly option. Additionally, veneers reduce sawdust waste.

- Aesthetically Appealing: Veneers offer you complete aesthetic control, as there is a huge range of finishes and designs to choose from. This improves the aesthetics of your space very easily.

- High Stability: Veneers are not as prone to warping and splitting due to liquid damage. This is because veneers are a layered construction.

Wood Veneer Pieces: Manufacturing Process

The wood veneer manufacturing process is quite simple. Wood veneer is sliced or peeled into thin layers of natural wood. There are various methods to do this:

- Rotary cutting

- Slicing

- Half-round lathing

The process of this slicing allows for the natural grain pattern of the wood to remain in place, making each veneer unique and special. As veneer is not cut, but sliced, from logs, no wood is wasted as sawdust. You can finish and stain wood veneer just like real wood. These sliced pieces can also be cut further with a veneer saw.

Veneers are often pressed onto laminate to attach to thicker materials, like plywood, particle board, fiberboard, or medium density fiberboard (MDF). This can create structured flat panels such as doors, which can be a fantastic alternative to hardwood. This process makes the wood more stable. It still expands and contracts, but not as much as solid wood.

Wood Veneer: Care and Maintenance

The pros at WoodenAve have got you covered with the best care and maintenance tips:

- Cleaning Veneers: Use a soft, damp cloth and a mild detergent to clean your veneers. Do not use abrasive cleaners, as these can damage the surface of your wood.

- Consistent Maintenance: To make sure that your veneers always look good, regularly apply wood polish or conditioner. This will also help the veneer maintain its luster and protect the finish. It can be time-consuming, but it’s completely worth it.

- Avoid Moisture: Protect your veneers from excessive moisture wherever possible, as this can damage the adhesive bond over long periods of time. You can treat your veneers with a finish of polyurethane to make them more water-resistant.

Common Mistakes When Using Wood Veneer

- Using the Wrong Adhesive: If you use the wrong adhesive, it can result in delamination or peeling.

- Failing to Prepare the Surface: If you don’t properly prepare the substrate, it can affect the quality of your veneer finish and its adhesion.

- Ignoring Environmental Conditions: Humidity and temperature can lead to warping and cracking, especially exposure to direct sunlight. Make sure your veneers are long-lasting by paying careful attention to your environment.

Wood Veneer: Sustainable Modern Designs

So, why buy wood veneers? Other than clearly being significant in modern woodworking and design, its practicality, affordability, sustainability, and aesthetically pleasing nature make it a great design choice for any space.

Wood veneers offer a versatile alternative to solid wood in a variety of areas, from home kitchens to commercial projects. If you need some advice before making your veneer choice, get in touch with the team at WoodenAve. We’re always happy to help!

FAQs on What is Wood Veneer?

Can wood veneer be sanded?

Yes, wood veneer can be sanded. However, wood veneer is actually quite difficult to sand because you have to be incredibly gentle. If you or a woodworker intends on sanding a piece of wood veneer, it’d be best to start by hand or with a palm sander. Don’t use anything coarser than 100-grit and don’t sand against the wood grain. The slightest mistake can completely ruin real wood veneer.

Can wood veneer get wet?

No, wood veneer should not get wet. Wood veneer isn’t waterproof, so if it gets too wet, it will warp and begin to lift. Sometimes, if it gets completely soaked, it can become soft and lose its texture. It’s important to keep your wood veneer products as dry as possible.

What are the disadvantages of veneer wood?

The disadvantages of veneer wood are related to color variations, delamination, scratches, and challenging maintenance. While wood veneers are a great furniture option, the thin layers of natural wood can show different color variations, depending on growth conditions.

Exposure to moisture can cause the veneer to separate, too. High-quality wood veneer is more susceptible to scratches than solid wood furniture because it’s made from natural sources. Additionally, damaged veneer is not as easy to repair as other options.

Back to Top: What is Wood Veneer?