Wood Veneers

Wood veneers are very important in the modern building and decoration material industry. For example, oak and walnut veneers apply in interiors surface decoration for decades. But, they are still the most popular wood veneer species until today.

There are two large sorts of real wood veneers, natural hardwood veneer and reconstituted veneer. Moreover, natural wood veneers are subdivided into many types of veneers according to the veneer specie, veneer thickness, processing, and application.

People like to buy 0.5 mm, 0.55 mm or 0.6 mm thick veneer sheets to apply for interior decoration or woodworking DIY. While massive used in building and construction for doors, wood cabinets, furniture, wallcovering panels, veneering plywood, veneered MDF, etc.

Download PDF : 5 main types of wood veneer

Download PDF : 10 points checklist before you buy wood veneers

5 Main Types of Wood Veneer

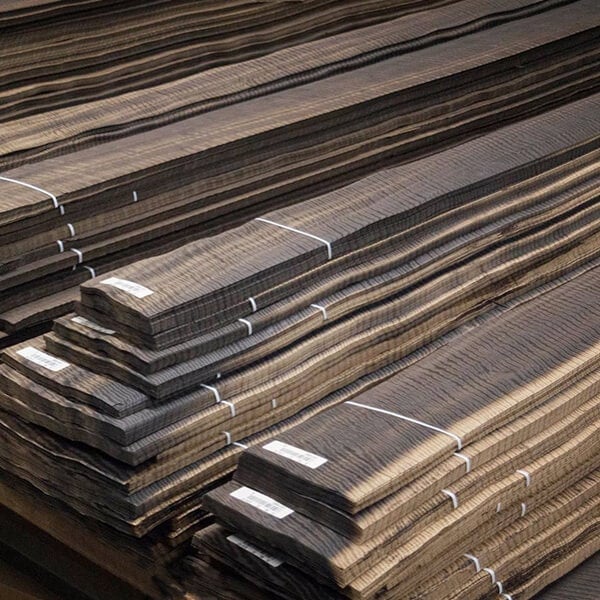

Natural Wood Veneer

Natural wood veneer is sourced from the trunk of a tree by slicing large wooden blocks to create raw veneer sheets. Typically, European and American manufacturers produce thicker natural veneers.

We offer a range of options, including both thick and thin veneers, such as paper-thin veneers, 0.5 mm standard veneers, rough cut veneers, engineered flooring top-layer veneers, and exotic wood veneers. Additionally, we provide processed natural veneers like dyed veneers, smoked veneers, and book-matched veneers.

Common veneer species we supply include:

- Ash veneer, Teak veneer, Maple veneer, Cherry veneer, Ebony veneer

- Rosewood veneer, Sapele veneer, Anigre veneer, Eucalyptus veneer, Bamboo veneer, etc.

Engineered Veneer

Engineered veneer is produced by rotary cutting raw natural veneers from wood species like Basswood, Obeche (Ayous), or Poplar. These veneers are dyed and then laminated together to form a wood block. By slicing these man-made wood blocks, we obtain the final engineered veneer, also known as reconstituted veneer.

With over 10 different manufacturing processes, engineered veneer replicates the appearance of natural wood species or even mimics the look of exotic and rare woods. However, it is free from the imperfections commonly found in natural veneers.

One of the key advantages of engineered veneer is its ability to be produced in large quantities with consistent color and grain patterns across each sheet. This makes it ideal for large-scale projects, where natural veneers may lack the consistency in color and grain.

Additionally, when it comes to expensive wood species like walnut, rosewood, ebony, or teak, engineered veneer is often a more cost-effective alternative to natural wood veneers.

Paper-backed and fleece-backed (non-woven fabric) veneers are the most common types of veneer backing. These backings are bonded to top-quality veneer sheets to maintain the integrity of individual veneer layers.

We typically work with standard veneer thicknesses of 0.5 mm to 0.6 mm, which are glued together side by side. Additionally, we can also work with paper-thin veneers ranging from 0.1 mm to 0.2 mm (10 Mil), which can be used to create full-width sheets of 600 mm, 620 mm, or 1220 mm (2 ft, 4 ft).

10 mil paper-backed veneer is a great option for most woodworking projects, though care must be taken during the bonding process to avoid issues like bubbling.

For curved projects, such as door frames, picture frames, profiles, skirting, and edgebanding, fleece-backed veneer is the ideal choice, as it provides better flexibility and durability.

Veneer rolls are commonly used for veneer edge banding and profile wrapping. These rolls consist of finger-jointed wood veneers, with 15 mm to 60 mm width rolls typically used for edge banding, and 60 mm to 300 mm width rolls used for profile wrapping.

We offer both natural veneer edge banding and reconstituted veneer edge banding, as well as natural veneer profile wrapping and reconstituted profile wrapping veneer. Additionally, UV pre-finished veneers are available for both edge banding and profile wrapping applications.

Our most commonly used wood species include:

- American woods such as White Oak, Red Oak, Walnut, Cherry, and Maple

- African woods such as Sapele, Bubinga, Zebrano, Anigre, and Okoume

- Ebony and Teak from Asia

We offer three main types of specialty and rare veneers: woven veneer, burl veneer, and veneer layons.

-

Woven Veneer: These are 100% handmade wood veneer sheets created by weaving veneer strips together to form intricate design patterns.

-

Burl Veneer: We supply both small, thick burl veneers and ultra-thin burl veneers that can be matched to large sheet sizes. Our burl veneer options include species such as Mappa Burl, Walnut Burl, Golden Burl, Gold Nanmu Burl, Camphor Burl, Fir Burl, and more.

-

Veneer Layons: These are fleece or paper-backed veneer sheets carefully matched according to joinery or furniture design requirements. We offer patching or matching of veneer sheets to standard panel and door sizes, as well as cut-to-size services for a variety of shapes and sizes.

Wood Veneers in the Modern Market

New types of wood veneer designs are constantly emerging in the international market, providing buyers with a growing range of exciting options.

In addition to traditional wood veneers, many manufacturers now use stainless steel and aluminum sheets to mimic the appearance of exotic and rare wood species. Some even laminate aluminum sheets with wood veneer to create unique finishes.

However, choosing and applying wood veneer can still present challenges. One of the main concerns is veneer quality grade, which is crucial when purchasing in large quantities. Different buyers and sellers often have their own standards for veneer quality, which can lead to confusion. This is why many professional veneer buyers visit suppliers in China to inspect natural veneer stocks and negotiate prices in person.

Lastly, most wood veneers are applied to plywood, MDF, or particleboard to produce products such as wood doors, cabinets, furniture, and wallcoverings. The stability and smoothness of the substrate are essential to avoid veneering issues during production.

Why Choose WoodenAve as your Wood Veneer Supplier

Back to top: Wood Veneers